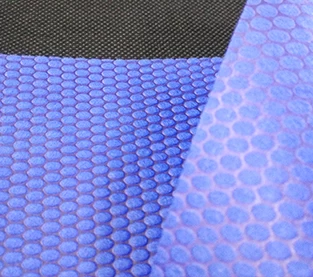

Product: ES Material Fiber Nonwoven Fabric For Packaging

Raw Material: PP+PE

Nonwoven Technology: thermal bonded

Dotted Design: dot or plain

Gram: 25 gsm - 30 gsm

Color: White

Specification: custom

Sample: Can be provided without charge, freight to be collect

Applications:

Medical(20-60gsm): face masks,diapers,bed sheets,curtains,pillow covers,sanitary,etc

Packaging(25-30gsm): tea bag, coffee bag/filter paper, dust-proof covers.etc

Product: ES Thermal Bonded Non Woven Fabric For Tea Bag

Raw Material: PP+PE

Nonwoven Technology: thermal bonded

Dotted Design: dot or plain

Gram: 25 gsm - 30 gsm

Color: White

Specification: custom

Sample: Can be provided without charge, freight to be collect

Applications:

Medical(20-60gsm): face masks,diapers,bed sheets,curtains,pillow covers,sanitary,etc

Packaging(25-30gsm): tea bag, coffee bag/filter paper, dust-proof covers.etc

Product: Composite Non Woven Paper Desiccant Packaging Material

MOQ: 1000 kg

Material: Composite Non Woven Paper

Specification: Custom sizes.

Design: Welcome custom logo and design. Welcome OEM.

Color: Full Color of CMYK,Pantone Color as customer requirements

Weight: Based on size & material,thickness

Delivery Time: 10-15 days after confirmed the final artwork and order

Product: Desiccant Wrapping Paper

MOQ: 1000 kg

Material: DuPont Material

Specification: Custom sizes.

Design: Welcome custom logo and design. Welcome OEM.

Color: Full Color of CMYK,Pantone Color as customer requirements

Weight: Based on size & material,thickness

Delivery Time: 10-15 days after confirmed the final artwork and order

Product: Bi-component Non Woven Fabric Desiccant Packaging Material

MOQ: 1000 kg

Material: Bi-component Non Woven Fabric

Specification: Custom sizes.

Design: Welcome custom logo and design. Welcome OEM.

Color: Full Color of CMYK,Pantone Color as customer requirements

Weight: Based on size & material,thickness

Delivery Time: 10-15 days after confirmed the final artwork and order

Product: Spunbond Non Woven Fabric Custom Desiccant Packaging Material

MOQ: 1000 kg

Material: Spunbond Non Woven Fabric

Specification: Custom sizes.

Design: Welcome custom logo and design. Welcome OEM.

Color: Full Color of CMYK,Pantone Color as customer requirements

Weight: Based on size & material,thickness

Delivery Time: 10-15 days after confirmed the final artwork and order

The dyeing method of the nonwoven fabric isbasically the same as that of the conventional textile. However, since nonwovenfabrics, particularly thin nonwoven fabrics, have low strength and are easilydeformed under stress, these factors must be sufficiently considered in actualdyeing, and appropriate methods and equipment should be selected.

1. Dyeing method

Infection is a method in which a loosefiber or a non-woven fabric is infiltrated into a dyeing liquid for a certainperiod of time, and the dyeing liquid or fabric is continuously turned to makethe dye uniformly dyed on the textile. There are many dyeing liquids used forinfestation, that is, the bath ratio is large, and when the percentage ofdyeing is not high, the dye utilization rate is not high, and the utilizationof the residual liquid can be used to improve the utilization rate of the dye.When dip dyeing, the uniform flow of the dye solution and uniform temperatureare two important factors to ensure the dyeing quality. The dyeing level can beimproved by prolonging the dyeing time.

Dyeing is the immersion of the fabric intothe dyeing liquid for a short time. After rolling, the dyeing liquid is evenlyrolled into the inner space of the fabric, the excess dyeing liquid is squeezedaway, and then the dye in the tissue space is dyed by steaming or hot-meltingtreatment. Pad dyeing is generally used in the production and processing oflarge quantities of fabrics. Unlike dip dyeing, fabrics are only immersed indye liquor for a few seconds or tens of seconds. Evenly padding can make thedyeing uniform, the fabric has good wettability, and the dyeing liquid entersthe fabric to replace the air quickly, so that the fabric after rolling can beevenly distributed. The dyeing liquid on the fabric after padding should not betoo large. It is measured by the liquid carrying rate (percentage of the clothabsorbing liquid and the dry cloth weight after rolling). Generally, the cottonfabric is about 70%, the viscose fabric is about 90%, and the polyester fabricis about 30. %. If the liquid carrying rate is too large, when drying, thesurface moisture of the fabric will evaporate, and the dyeing liquid in thetissue space will move to the surface to evaporate, and the dye will "iceshift", resulting in color shift. The padding method may be one dip onerolling, two dip two rolling, or the like. Some dyes do not use steam afterpadding, which saves energy by stacking and dyeing for a long time.

2. Dyeing equipment

The requirements for the dyeing equipmentare mainly in the dyeing process, so that the nonwoven fabric can be dyedthoroughly and the damage is small. In addition, the dyeing equipment is alsorequired to adapt to the needs of high-speed textile development, high-speedcontinuous, automation, low energy consumption, low wastewater discharge,multi-variety, small batch, and the like. There are many kinds of dyeingequipments, which are classified according to the form of dyed textiles. Thedyeing equipment is divided into fabric dyeing machine, yarn dyeing machine andbulk fiber dyeing machine: according to the pressure and temperature conditionsduring dyeing, the dyeing equipment is divided into normal temperature andatmospheric pressure dyeing machine and high temperature and high pressuredyeing. In addition, it can be classified as intermittent or continuous, fabricflat or rope.

The bulk fiber dyeing machine uses a bulkfiber dyeing machine, such as a basket dyeing machine. As shown in Figure 11-1,the hanging basket dyeing machine puts the loose fiber into the hanging basket1, and the hanging basket is re-introduced into the dyeing tank 2. After thegroove cover 6 is tightened, the dyeing liquid is pushed by the circulationpump 3 from the liquid storage tank 4. The central tube 5 to the basket flowsout, passes through the fibers and the outer wall of the basket, and returns tothe center tube to form a dyeing cycle. The dye liquor cycle can also be reversed.After the dyeing is completed, the residual liquid is transferred to the liquidstorage tank, and the water is washed, and finally the hanging basket islifted, and the hanging tube is directly dehydrated by the centrifuge.

3. Dyeing process

Dorolan E metal complex dye is used fordyeing PAPU imitation leather non-woven fabric. It has high dyeing rate, fullcolor, good leveling, good dyeability and good color fastness. The degree is upto level 3 and above. At the same time, since the PAPU leather-like nonwovenfabric is thicker than the conventional textile fabric, when dyeing withDorolan metal complex dye, for some color varieties, by slowing down theheating rate and prolonging the holding time, it is more advantageous toimprove the leather-like nonwoven fabric. Level dyeing, translucency and colorfastness. The dissolution ratio is 1:50, and the specific dyeing curve is shownin Figure 11-2.

The dyeing process carried outsimultaneously with the finishing process is suitable for the dyeing of non-wovenfabrics for curtains. The simultaneous dyeing and finishing mainly consists ofthe following processes:inspection-unwinding-dipping-drying-calendering-rolling.