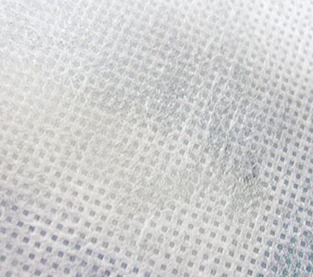

Product: ES Material Fiber Nonwoven Fabric For Packaging

Raw Material: PP+PE

Nonwoven Technology: thermal bonded

Dotted Design: dot or plain

Gram: 25 gsm - 30 gsm

Color: White

Specification: custom

Sample: Can be provided without charge, freight to be collect

Applications:

Medical(20-60gsm): face masks,diapers,bed sheets,curtains,pillow covers,sanitary,etc

Packaging(25-30gsm): tea bag, coffee bag/filter paper, dust-proof covers.etc

Product: ES Thermal Bonded Non Woven Fabric For Tea Bag

Raw Material: PP+PE

Nonwoven Technology: thermal bonded

Dotted Design: dot or plain

Gram: 25 gsm - 30 gsm

Color: White

Specification: custom

Sample: Can be provided without charge, freight to be collect

Applications:

Medical(20-60gsm): face masks,diapers,bed sheets,curtains,pillow covers,sanitary,etc

Packaging(25-30gsm): tea bag, coffee bag/filter paper, dust-proof covers.etc

Product: Composite Non Woven Paper Desiccant Packaging Material

MOQ: 1000 kg

Material: Composite Non Woven Paper

Specification: Custom sizes.

Design: Welcome custom logo and design. Welcome OEM.

Color: Full Color of CMYK,Pantone Color as customer requirements

Weight: Based on size & material,thickness

Delivery Time: 10-15 days after confirmed the final artwork and order

Product: Desiccant Wrapping Paper

MOQ: 1000 kg

Material: DuPont Material

Specification: Custom sizes.

Design: Welcome custom logo and design. Welcome OEM.

Color: Full Color of CMYK,Pantone Color as customer requirements

Weight: Based on size & material,thickness

Delivery Time: 10-15 days after confirmed the final artwork and order

Product: Bi-component Non Woven Fabric Desiccant Packaging Material

MOQ: 1000 kg

Material: Bi-component Non Woven Fabric

Specification: Custom sizes.

Design: Welcome custom logo and design. Welcome OEM.

Color: Full Color of CMYK,Pantone Color as customer requirements

Weight: Based on size & material,thickness

Delivery Time: 10-15 days after confirmed the final artwork and order

Product: Spunbond Non Woven Fabric Custom Desiccant Packaging Material

MOQ: 1000 kg

Material: Spunbond Non Woven Fabric

Specification: Custom sizes.

Design: Welcome custom logo and design. Welcome OEM.

Color: Full Color of CMYK,Pantone Color as customer requirements

Weight: Based on size & material,thickness

Delivery Time: 10-15 days after confirmed the final artwork and order

First, in terms of materials, PP / PE andnonwoven fabric(China Spun Bonded Non Woven Supplier) (in this case, PET nonwoven fabric) use polymer materialshaving different glass transition temperatures. Simply put, the glasstransition temperature of PP / PE is lower than room temperature, and as thetemperature increases, the film material becomes softer (strictly, themolecules are locally accelerated).

For example, the internal temperature ofthe battery is about 60 °C during charging and discharging, the electrode will repeatedlyexpand and contract, and the PP / PE film will gradually become smaller againand again under the action of shrinkage stress.

However, with PET nonwoven fabric(Non Woven Polyester Fabric Wholesale), theglass transition temperature is above 80 ° C, which not only softens with increasing temperature, but alsostabilizes the porosity well and makes the battery cycle life longer.

In fact, the same phenomenon has beenconfirmed when using nickel-hydrogen batteries.

High-rate nickel-metal hydride batteries,the internal temperature of the battery will exceed 100 °C, using a general diaphragm,or a nylon material of a general diaphragm, under the conditions of D-type 200battery discharge, only a few charge and discharge cycles, the diaphragm willquickly degenerate.

If you use a special nylon diaphragm with ahigh glass transition temperature, battery life can be leaps and bounds.

In the future, many facts will be continuously verified in experiments. For example, a non-woven membrane(Non Woven Polyester Material Factory) made ofglass fiber can also be used for lithium ion batteries, as well as PP / PEmicroporous membranes. Large, but the time of lithium-ion battery is mainlyused for cameras and mobile phones. The thickness of the diaphragm is thin andhas a closed-cell function, which leads to the development of microporousmembranes.