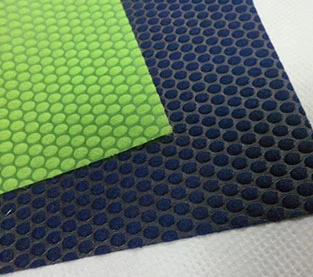

Product: ES Material Fiber Nonwoven Fabric For Packaging

Raw Material: PP+PE

Nonwoven Technology: thermal bonded

Dotted Design: dot or plain

Gram: 25 gsm - 30 gsm

Color: White

Specification: custom

Sample: Can be provided without charge, freight to be collect

Applications:

Medical(20-60gsm): face masks,diapers,bed sheets,curtains,pillow covers,sanitary,etc

Packaging(25-30gsm): tea bag, coffee bag/filter paper, dust-proof covers.etc

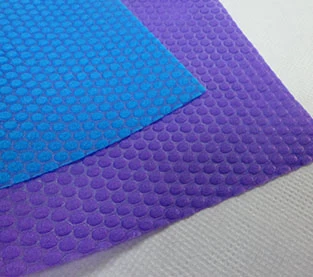

Product: ES Thermal Bonded Non Woven Fabric For Tea Bag

Raw Material: PP+PE

Nonwoven Technology: thermal bonded

Dotted Design: dot or plain

Gram: 25 gsm - 30 gsm

Color: White

Specification: custom

Sample: Can be provided without charge, freight to be collect

Applications:

Medical(20-60gsm): face masks,diapers,bed sheets,curtains,pillow covers,sanitary,etc

Packaging(25-30gsm): tea bag, coffee bag/filter paper, dust-proof covers.etc

Product: Composite Non Woven Paper Desiccant Packaging Material

MOQ: 1000 kg

Material: Composite Non Woven Paper

Specification: Custom sizes.

Design: Welcome custom logo and design. Welcome OEM.

Color: Full Color of CMYK,Pantone Color as customer requirements

Weight: Based on size & material,thickness

Delivery Time: 10-15 days after confirmed the final artwork and order

Product: Desiccant Wrapping Paper

MOQ: 1000 kg

Material: DuPont Material

Specification: Custom sizes.

Design: Welcome custom logo and design. Welcome OEM.

Color: Full Color of CMYK,Pantone Color as customer requirements

Weight: Based on size & material,thickness

Delivery Time: 10-15 days after confirmed the final artwork and order

Product: Bi-component Non Woven Fabric Desiccant Packaging Material

MOQ: 1000 kg

Material: Bi-component Non Woven Fabric

Specification: Custom sizes.

Design: Welcome custom logo and design. Welcome OEM.

Color: Full Color of CMYK,Pantone Color as customer requirements

Weight: Based on size & material,thickness

Delivery Time: 10-15 days after confirmed the final artwork and order

Product: Spunbond Non Woven Fabric Custom Desiccant Packaging Material

MOQ: 1000 kg

Material: Spunbond Non Woven Fabric

Specification: Custom sizes.

Design: Welcome custom logo and design. Welcome OEM.

Color: Full Color of CMYK,Pantone Color as customer requirements

Weight: Based on size & material,thickness

Delivery Time: 10-15 days after confirmed the final artwork and order

Non-stick performance

Teflon is a non-stick "miracle"that was invented 50 years ago by Dr. Plunkett of DuPont. Although from this time on, many new non-stick products have entered the market one after another,but they are only slightly better. Because the non-stick properties of the product are very good at first, people are working hard to improve its wear resistance. However, even the best non-stick properties of Teflon products donot prevent the PSA hot melt adhesive from sticking to the deflection rolls.Even if the coating is durable enough, it can only last for a few days at this production speed.

Twenty years ago, this product, which improved the wear resistance and non-stick properties of the coating, wasdeveloped to optimize non-stick properties by creating a very hard matrix and applying a non-stick coating to the peaks and valleys of the substrate.performance. The substrate is in the form of a thermal spray applied by applying a metal layer to the substrate. This makes the surface very rough and full of hard spots, which protects the non-stick coating applied to it. The creation of the nodular surface also enhances the non-stick properties.

Wear resistance

The microhardness, bond strength and application method of the matrix particles are the key to wear resistance. Evena hard substrate is useless when the non-stick coating of the top layer isworn. As an example, carbide is a very hard and wear resistant substrate. It iswidely used as a sawtooth on a saw blade cutting tool. If a wear resistant coating is applied to the carbide, the material(PP Nonwoven Fabric Company) is too dense to allow the polymer coating to penetrate. If it is applied to a sponge-like matrix, thepolymer has room for penetration. A problem with porous substrates is that thebond strength of the individual particles is reduced, resulting in premature wear and tear of the tungsten particles from the cobalt binder. In addition,carbides tend to have sharp corners that drag and pull the nonwoven(PP Nonwovens On Sales) or hook thepoly.