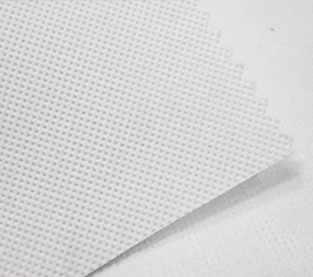

Product: ES Material Fiber Nonwoven Fabric For Packaging

Raw Material: PP+PE

Nonwoven Technology: thermal bonded

Dotted Design: dot or plain

Gram: 25 gsm - 30 gsm

Color: White

Specification: custom

Sample: Can be provided without charge, freight to be collect

Applications:

Medical(20-60gsm): face masks,diapers,bed sheets,curtains,pillow covers,sanitary,etc

Packaging(25-30gsm): tea bag, coffee bag/filter paper, dust-proof covers.etc

Product: ES Thermal Bonded Non Woven Fabric For Tea Bag

Raw Material: PP+PE

Nonwoven Technology: thermal bonded

Dotted Design: dot or plain

Gram: 25 gsm - 30 gsm

Color: White

Specification: custom

Sample: Can be provided without charge, freight to be collect

Applications:

Medical(20-60gsm): face masks,diapers,bed sheets,curtains,pillow covers,sanitary,etc

Packaging(25-30gsm): tea bag, coffee bag/filter paper, dust-proof covers.etc

Product: Composite Non Woven Paper Desiccant Packaging Material

MOQ: 1000 kg

Material: Composite Non Woven Paper

Specification: Custom sizes.

Design: Welcome custom logo and design. Welcome OEM.

Color: Full Color of CMYK,Pantone Color as customer requirements

Weight: Based on size & material,thickness

Delivery Time: 10-15 days after confirmed the final artwork and order

Product: Desiccant Wrapping Paper

MOQ: 1000 kg

Material: DuPont Material

Specification: Custom sizes.

Design: Welcome custom logo and design. Welcome OEM.

Color: Full Color of CMYK,Pantone Color as customer requirements

Weight: Based on size & material,thickness

Delivery Time: 10-15 days after confirmed the final artwork and order

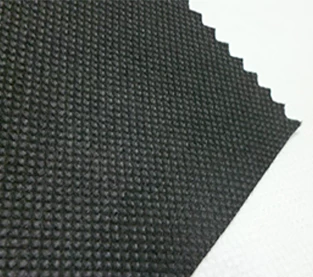

Product: Bi-component Non Woven Fabric Desiccant Packaging Material

MOQ: 1000 kg

Material: Bi-component Non Woven Fabric

Specification: Custom sizes.

Design: Welcome custom logo and design. Welcome OEM.

Color: Full Color of CMYK,Pantone Color as customer requirements

Weight: Based on size & material,thickness

Delivery Time: 10-15 days after confirmed the final artwork and order

Product: Spunbond Non Woven Fabric Custom Desiccant Packaging Material

MOQ: 1000 kg

Material: Spunbond Non Woven Fabric

Specification: Custom sizes.

Design: Welcome custom logo and design. Welcome OEM.

Color: Full Color of CMYK,Pantone Color as customer requirements

Weight: Based on size & material,thickness

Delivery Time: 10-15 days after confirmed the final artwork and order

The reasons that affect the flame retardancy of flame retardant nonwovens are as follows:

1. Conventional polyester cotton has an oxygen limit index of 20-22, which is a type of combustible fiber. It is easy to ignite but has a slower burning rate.

2. If the polyester slice is modified and denatured, it will have a flame-resistant effect. Most of the long-acting flame-retardant fibers(Embossed Non Woven Fabric Company) use denatured polyester chips to produce flame-retardant polyester cotton. The main modifier is a phosphorus compound. The use of phosphorus in high heat will combine with oxygen in the air to reduce- Characteristics achieve good flame retardant effect-fruit.

3. Another method to make polyester cotton flame retardant is surface treatment. This kind of product thinks that the treatment agent will reduce after being processed for many times-low flame retardant effect-fruit.

4. However, if the fiber is stained with oil that is easy to support combustion or the use of silicone oil that can set polyester cotton, polyester cotton will reduce-low flame retardant effect-fruit. Especially-when the polyester cotton containing SILICONE oil agent is exposed to flame, the fiber cannot shrink and burn.

5. Polyester cotton has the characteristics of shrinking when encountering high heat. When the fiber shrinks when it encounters flame, it is difficult to ignite due to shrinkage and it will produce a suitable flame retardant effect.

Flame retardant non-woven fabrics(Flame Retardant Nonwovens Supplier) are moisture-proof, breathable, flexible, non-combustible, easy to decompose, rich in color, low in price, and recyclable. The reasons that affect the flame retardancy of flame retardant non-woven fabrics are mainly those described above, and these reasons are also what we need to understand.