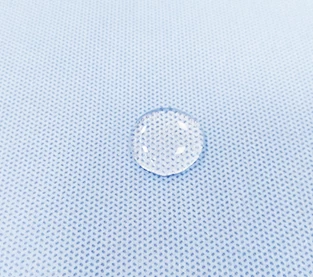

Product: ES Material Fiber Nonwoven Fabric For Packaging

Raw Material: PP+PE

Nonwoven Technology: thermal bonded

Dotted Design: dot or plain

Gram: 25 gsm - 30 gsm

Color: White

Specification: custom

Sample: Can be provided without charge, freight to be collect

Applications:

Medical(20-60gsm): face masks,diapers,bed sheets,curtains,pillow covers,sanitary,etc

Packaging(25-30gsm): tea bag, coffee bag/filter paper, dust-proof covers.etc

Product: ES Thermal Bonded Non Woven Fabric For Tea Bag

Raw Material: PP+PE

Nonwoven Technology: thermal bonded

Dotted Design: dot or plain

Gram: 25 gsm - 30 gsm

Color: White

Specification: custom

Sample: Can be provided without charge, freight to be collect

Applications:

Medical(20-60gsm): face masks,diapers,bed sheets,curtains,pillow covers,sanitary,etc

Packaging(25-30gsm): tea bag, coffee bag/filter paper, dust-proof covers.etc

Product: Composite Non Woven Paper Desiccant Packaging Material

MOQ: 1000 kg

Material: Composite Non Woven Paper

Specification: Custom sizes.

Design: Welcome custom logo and design. Welcome OEM.

Color: Full Color of CMYK,Pantone Color as customer requirements

Weight: Based on size & material,thickness

Delivery Time: 10-15 days after confirmed the final artwork and order

Product: Desiccant Wrapping Paper

MOQ: 1000 kg

Material: DuPont Material

Specification: Custom sizes.

Design: Welcome custom logo and design. Welcome OEM.

Color: Full Color of CMYK,Pantone Color as customer requirements

Weight: Based on size & material,thickness

Delivery Time: 10-15 days after confirmed the final artwork and order

Product: Bi-component Non Woven Fabric Desiccant Packaging Material

MOQ: 1000 kg

Material: Bi-component Non Woven Fabric

Specification: Custom sizes.

Design: Welcome custom logo and design. Welcome OEM.

Color: Full Color of CMYK,Pantone Color as customer requirements

Weight: Based on size & material,thickness

Delivery Time: 10-15 days after confirmed the final artwork and order

Product: Spunbond Non Woven Fabric Custom Desiccant Packaging Material

MOQ: 1000 kg

Material: Spunbond Non Woven Fabric

Specification: Custom sizes.

Design: Welcome custom logo and design. Welcome OEM.

Color: Full Color of CMYK,Pantone Color as customer requirements

Weight: Based on size & material,thickness

Delivery Time: 10-15 days after confirmed the final artwork and order

1. Three-layer(SMS Polypropylene Fabric Factory) structure with enhanced surface

2. The core layer-the main waterproof layer uses linear low-density polyethylene (LLDPE) with a higher branch ratio (more macromolecular side chains), which has extensibility, impermeability, flexibility, puncture resistance, and low temperature resistance Performance is better.

3. The surface is made of polypropylene non-woven fabric, which solves the problem of large linear expansion coefficient of polyethylene by compounding with the core layer. The surface roughness of the product is increased, the friction coefficient of the product is improved, and the bonding problem of the composite coil is solved, and cement bonding is realized.

Structural characteristics of waterproof polypropylene non-woven fabric(Nonwoven SMS Wholesale):

It has strong impermeability, high tensile strength, good low temperature flexibility, low linear expansion coefficient, easy bonding, large friction coefficient, good stability, non-toxic, strong deformation adaptability, wide temperature range, long service life, etc. The comprehensive technical performance. Polyethylene and polypropylene (polypropylene) are chemically stable, resistant to corrosion, mildew, and ozone, while polypropylene has good mechanical properties.

Features of waterproof polypropylene non-woven fabric(Medical SMMS Material Manufacturer):

1. Polymer waterproofing membrane belongs to the series of synthetic polymer waterproofing membranes. In addition to fully having all the advantages of synthetic polymer membranes, its own outstanding feature lies in the network structure on its surface, which gives it its own Unique performance-cement bonding.

2. Because the polymer composite coil can be directly bonded with cement, it will not be affected by the moisture content of the base layer during the construction process. It can be constructed as long as there is no clear water. This is not available in other waterproof membranes.

3. Due to the rough surface of the polymer composite coil and the large friction coefficient, it can be directly buried in sand and has sufficient stability when used in water conservancy projects.

4. Since the polymer composite coil can be directly bonded to the cement material during the solidification process, it can be directly designed in the structure of the cement material.