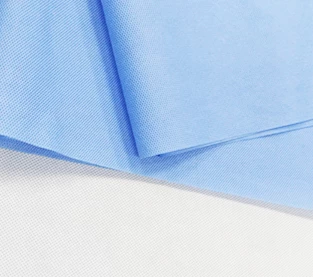

Product: ES Material Fiber Nonwoven Fabric For Packaging

Raw Material: PP+PE

Nonwoven Technology: thermal bonded

Dotted Design: dot or plain

Gram: 25 gsm - 30 gsm

Color: White

Specification: custom

Sample: Can be provided without charge, freight to be collect

Applications:

Medical(20-60gsm): face masks,diapers,bed sheets,curtains,pillow covers,sanitary,etc

Packaging(25-30gsm): tea bag, coffee bag/filter paper, dust-proof covers.etc

Product: ES Thermal Bonded Non Woven Fabric For Tea Bag

Raw Material: PP+PE

Nonwoven Technology: thermal bonded

Dotted Design: dot or plain

Gram: 25 gsm - 30 gsm

Color: White

Specification: custom

Sample: Can be provided without charge, freight to be collect

Applications:

Medical(20-60gsm): face masks,diapers,bed sheets,curtains,pillow covers,sanitary,etc

Packaging(25-30gsm): tea bag, coffee bag/filter paper, dust-proof covers.etc

Product: Composite Non Woven Paper Desiccant Packaging Material

MOQ: 1000 kg

Material: Composite Non Woven Paper

Specification: Custom sizes.

Design: Welcome custom logo and design. Welcome OEM.

Color: Full Color of CMYK,Pantone Color as customer requirements

Weight: Based on size & material,thickness

Delivery Time: 10-15 days after confirmed the final artwork and order

Product: Desiccant Wrapping Paper

MOQ: 1000 kg

Material: DuPont Material

Specification: Custom sizes.

Design: Welcome custom logo and design. Welcome OEM.

Color: Full Color of CMYK,Pantone Color as customer requirements

Weight: Based on size & material,thickness

Delivery Time: 10-15 days after confirmed the final artwork and order

Product: Bi-component Non Woven Fabric Desiccant Packaging Material

MOQ: 1000 kg

Material: Bi-component Non Woven Fabric

Specification: Custom sizes.

Design: Welcome custom logo and design. Welcome OEM.

Color: Full Color of CMYK,Pantone Color as customer requirements

Weight: Based on size & material,thickness

Delivery Time: 10-15 days after confirmed the final artwork and order

Product: Spunbond Non Woven Fabric Custom Desiccant Packaging Material

MOQ: 1000 kg

Material: Spunbond Non Woven Fabric

Specification: Custom sizes.

Design: Welcome custom logo and design. Welcome OEM.

Color: Full Color of CMYK,Pantone Color as customer requirements

Weight: Based on size & material,thickness

Delivery Time: 10-15 days after confirmed the final artwork and order

For example, doctors take 60g/m2 of wood pulp/polyester spunbond non-woven fabric(Medical Nonwovens Wholesale) for surgery, and it is obtained by water repellent finishing, antibacterial finishing, and antistatic finishing (flame retardant finishing agent can also be used if necessary). The process route is: padding Finishing liquid→drying→baking. In the drying process, the non-woven fabric is stretched to the required width and weight. After finishing, the fabric's weight, strength, liquid repellency, antistatic property, flame retardancy, and hand feel must be measured.