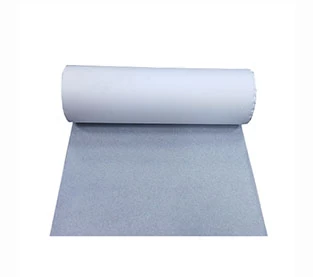

Product: ES Material Fiber Nonwoven Fabric For Packaging

Raw Material: PP+PE

Nonwoven Technology: thermal bonded

Dotted Design: dot or plain

Gram: 25 gsm - 30 gsm

Color: White

Specification: custom

Sample: Can be provided without charge, freight to be collect

Applications:

Medical(20-60gsm): face masks,diapers,bed sheets,curtains,pillow covers,sanitary,etc

Packaging(25-30gsm): tea bag, coffee bag/filter paper, dust-proof covers.etc

Product: ES Thermal Bonded Non Woven Fabric For Tea Bag

Raw Material: PP+PE

Nonwoven Technology: thermal bonded

Dotted Design: dot or plain

Gram: 25 gsm - 30 gsm

Color: White

Specification: custom

Sample: Can be provided without charge, freight to be collect

Applications:

Medical(20-60gsm): face masks,diapers,bed sheets,curtains,pillow covers,sanitary,etc

Packaging(25-30gsm): tea bag, coffee bag/filter paper, dust-proof covers.etc

Product: Composite Non Woven Paper Desiccant Packaging Material

MOQ: 1000 kg

Material: Composite Non Woven Paper

Specification: Custom sizes.

Design: Welcome custom logo and design. Welcome OEM.

Color: Full Color of CMYK,Pantone Color as customer requirements

Weight: Based on size & material,thickness

Delivery Time: 10-15 days after confirmed the final artwork and order

Product: Desiccant Wrapping Paper

MOQ: 1000 kg

Material: DuPont Material

Specification: Custom sizes.

Design: Welcome custom logo and design. Welcome OEM.

Color: Full Color of CMYK,Pantone Color as customer requirements

Weight: Based on size & material,thickness

Delivery Time: 10-15 days after confirmed the final artwork and order

Product: Bi-component Non Woven Fabric Desiccant Packaging Material

MOQ: 1000 kg

Material: Bi-component Non Woven Fabric

Specification: Custom sizes.

Design: Welcome custom logo and design. Welcome OEM.

Color: Full Color of CMYK,Pantone Color as customer requirements

Weight: Based on size & material,thickness

Delivery Time: 10-15 days after confirmed the final artwork and order

Product: Spunbond Non Woven Fabric Custom Desiccant Packaging Material

MOQ: 1000 kg

Material: Spunbond Non Woven Fabric

Specification: Custom sizes.

Design: Welcome custom logo and design. Welcome OEM.

Color: Full Color of CMYK,Pantone Color as customer requirements

Weight: Based on size & material,thickness

Delivery Time: 10-15 days after confirmed the final artwork and order

Medical masks are generally composed of non-woven fabrics, meltblown fabrics(Fabric Face Mask Factory), and ear wear materials, and the main structure is a three-layer (SMS) non-woven fabric. The main raw material of the S-layer non-woven fabric is polypropylene fiber material produced by homopolypropylene (PP) and peroxide modification, and the main material of the M layer is melt-blown cloth. The ear wear material is polypropylene plastic/polypropylene fiber + spandex.

Melt-blown cloth(Face Mask Cloth Company) refers to a non-woven fabric produced by the melt-blown method through the heat melting of its own fibers. After the material is electret treated, the fibers are charged and electrostatically capture the aerosol where the new coronavirus is located. Without changing the respiratory resistance, the filterability of meltblown cloth can reach 95%.

In fact, under normal circumstances, the annual production capacity of domestic masks is more than 5 billion, and this production capacity has accounted for half of the world. Under normal circumstances, the supply of raw materials for masks will not be too problematic.

However, it is clear that high-melt index fiber polypropylene is not all used in the production of medical masks. Coupled with the recent surge in demand for masks and hindered logistics, the supply and demand in the industry chain has changed significantly.

The demand for upstream high-melt fiber polypropylene will increase. Based on a two-month (20 million in the first month, 50 million in the next month), a total of 70 million masks will be produced. A total of 350 tons of high-melting index fiber polypropylene will be required, accounting for 0.037% of last year’s output. The growth is not large. However, due to the mismatch of demand and the impact of logistics and transportation, the price of raw materials will rise to a certain extent. Prior to this, the price of polypropylene was at a historically low level, and the price increase may bring certain benefits to the relevant manufacturers.

The same is true for production equipment. According to media reports, the current price of a set of mask production equipment has increased from 250,000 to 1.2 million, an increase of 380%; while the price of meltblown cloth has increased from 18,000 to 80,000, an increase of 440%. However, it is unclear how much of the price increase has overflowed into the hands of middlemen.

But it is worth mentioning that the processing of masks is very profitable. The profit of OEM production is even smaller.

Therefore, even if a large number of companies stop producing masks(N95 Material Wholesale), even if the price of masks rises significantly, the upsurge of making masks made by the whole people will not generate too much profit. In fact, in the case of malicious price increases of masks, the profit margins of all links in the industry chain are destined to not be too large (excluding the influence of black dealers).

As far as the entire industry chain is concerned, the surge in downstream demand has little stimulus to the growth of demand for raw materials, and the profit of downstream OEM production is relatively small. Therefore, the biggest benefit may be the midstream equipment suppliers (currently tight supply) and non-woven fabrics and melt-blown non-woven fabrics. Cloth enterprise.

As the tide recedes, what is the prospect of the mask industry?

In the short term, as the domestic epidemic has improved, but the epidemic in overseas countries such as Japan, South Korea, Italy, and Iran has continued to increase, domestic medical supplies import and export practitioners have considered exporting items under the premise of domestic demand.

Therefore, the concept of masks in the market may be able to continue for a certain period of time.

Under the global panic of the pandemic, masks seem to have become the only beneficiary sector. The longer the impact of new coronary pneumonia lasts, the more attention will be paid to the concept of masks.

Regardless of the surge in demand caused by the new crown pneumonia, what is the situation of China's mask industry?

As far as the midstream of the mask industry chain mentioned above (including non-woven fabrics and meltblown non-woven fabric manufacturers and equipment suppliers) is concerned, since the beginning of the Lunar New Year, its share price has risen quite well, and the rolling price-earnings ratio has also risen. . However, among the ten listed companies, there are six that have disclosed their annual performance expectations, and their profits and losses are divided by half.

It may be inferred from this that the prosperity of the domestic mask industry is not as ideal as expected.

When the industry demand returns to normal, will the mask industry that has done the best in the epidemic return to mediocrity?

For companies that cross-border production of masks, the National Development and Reform Commission and the Ministry of Finance have issued a document that clarifies that relevant medical protective materials are included in the national reserve. The government will purchase the masks and other protective materials produced by enterprises to increase productivity and expand production capacity.

But even so, the equipment purchased by the company at a premium may still be shelved or even sold at a discount, causing short-term losses.

For companies that are still in the industrial chain, the brand-building of downstream mask manufacturers and the capture of overseas markets may be the long-term development direction. Among the top ten brands of domestic mask sales, foreign brands account for six. The technical barriers of the mask industry are not high. As far as the industry is concerned, the reluctance of large domestic companies to enter the market because of the small profit margins in the market is the problem.

Once market attention and industry demand return to normal decline, what can mask concept stocks take to take off?