Product: ES Material Fiber Nonwoven Fabric For Packaging

Raw Material: PP+PE

Nonwoven Technology: thermal bonded

Dotted Design: dot or plain

Gram: 25 gsm - 30 gsm

Color: White

Specification: custom

Sample: Can be provided without charge, freight to be collect

Applications:

Medical(20-60gsm): face masks,diapers,bed sheets,curtains,pillow covers,sanitary,etc

Packaging(25-30gsm): tea bag, coffee bag/filter paper, dust-proof covers.etc

Product: ES Thermal Bonded Non Woven Fabric For Tea Bag

Raw Material: PP+PE

Nonwoven Technology: thermal bonded

Dotted Design: dot or plain

Gram: 25 gsm - 30 gsm

Color: White

Specification: custom

Sample: Can be provided without charge, freight to be collect

Applications:

Medical(20-60gsm): face masks,diapers,bed sheets,curtains,pillow covers,sanitary,etc

Packaging(25-30gsm): tea bag, coffee bag/filter paper, dust-proof covers.etc

Product: Composite Non Woven Paper Desiccant Packaging Material

MOQ: 1000 kg

Material: Composite Non Woven Paper

Specification: Custom sizes.

Design: Welcome custom logo and design. Welcome OEM.

Color: Full Color of CMYK,Pantone Color as customer requirements

Weight: Based on size & material,thickness

Delivery Time: 10-15 days after confirmed the final artwork and order

Product: Desiccant Wrapping Paper

MOQ: 1000 kg

Material: DuPont Material

Specification: Custom sizes.

Design: Welcome custom logo and design. Welcome OEM.

Color: Full Color of CMYK,Pantone Color as customer requirements

Weight: Based on size & material,thickness

Delivery Time: 10-15 days after confirmed the final artwork and order

Product: Bi-component Non Woven Fabric Desiccant Packaging Material

MOQ: 1000 kg

Material: Bi-component Non Woven Fabric

Specification: Custom sizes.

Design: Welcome custom logo and design. Welcome OEM.

Color: Full Color of CMYK,Pantone Color as customer requirements

Weight: Based on size & material,thickness

Delivery Time: 10-15 days after confirmed the final artwork and order

Product: Spunbond Non Woven Fabric Custom Desiccant Packaging Material

MOQ: 1000 kg

Material: Spunbond Non Woven Fabric

Specification: Custom sizes.

Design: Welcome custom logo and design. Welcome OEM.

Color: Full Color of CMYK,Pantone Color as customer requirements

Weight: Based on size & material,thickness

Delivery Time: 10-15 days after confirmed the final artwork and order

In the finishing of non-woven fabrics, the application of calenders is more and more, mainly has the following functions: by hot rolling, the non-woven fabric is glazed and flattened to maintain a uniform thickness, and the surface is formed with four convex patterns (rolling Flower), forming an open-cell structure, and the like. The calender used in the finishing of nonwoven fabrics(Flower Packaging Company) is basically the same as that used in conventional textile finishing, except that the roll combination or process conditions are slightly different.

After glazing and flattening, the products are mainly used in tablecloths, lining cloths, shoe villages, and artificial leather base fabrics, disposable materials, bed sheets, and soundproofing fabrics.

The glazing finishing is to smooth the surface of the cloth under a certain temperature and humidity condition by using a pair of pressing light rollers, so that the protruding fiber hairiness and the curved fiber are under the pressurized state, and are collapsed on the cloth surface, and compacted. , compact the nonwoven fabric(Gift Packing Material Supplier) to improve the gloss effect.

The purpose of uniform thickness rolling finishing is to make the thickness of the nonwoven fabric uniform and reach a certain thickness requirement. It is used in products such as artificial leather, filter materials and electrical insulation materials.

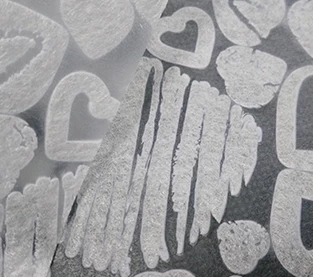

The embossing is mainly an artistic effect of causing a embossed, uneven pattern on the surface of the nonwoven fabric(Non Woven Flower Sleeves Company), and the purpose is to improve the appearance and improve the softness and feel of the cloth. It is suitable for decorative materials, needle punches, wall mats, carpets, bed sheets, tablecloths, artificial leather base fabrics, disposable products.