Product: ES Material Fiber Nonwoven Fabric For Packaging

Raw Material: PP+PE

Nonwoven Technology: thermal bonded

Dotted Design: dot or plain

Gram: 25 gsm - 30 gsm

Color: White

Specification: custom

Sample: Can be provided without charge, freight to be collect

Applications:

Medical(20-60gsm): face masks,diapers,bed sheets,curtains,pillow covers,sanitary,etc

Packaging(25-30gsm): tea bag, coffee bag/filter paper, dust-proof covers.etc

Product: ES Thermal Bonded Non Woven Fabric For Tea Bag

Raw Material: PP+PE

Nonwoven Technology: thermal bonded

Dotted Design: dot or plain

Gram: 25 gsm - 30 gsm

Color: White

Specification: custom

Sample: Can be provided without charge, freight to be collect

Applications:

Medical(20-60gsm): face masks,diapers,bed sheets,curtains,pillow covers,sanitary,etc

Packaging(25-30gsm): tea bag, coffee bag/filter paper, dust-proof covers.etc

Product: Composite Non Woven Paper Desiccant Packaging Material

MOQ: 1000 kg

Material: Composite Non Woven Paper

Specification: Custom sizes.

Design: Welcome custom logo and design. Welcome OEM.

Color: Full Color of CMYK,Pantone Color as customer requirements

Weight: Based on size & material,thickness

Delivery Time: 10-15 days after confirmed the final artwork and order

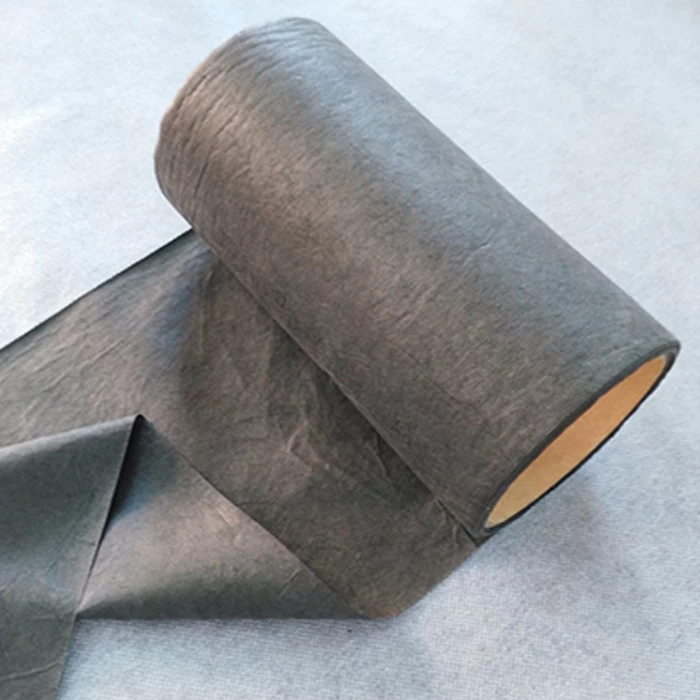

Product: Desiccant Wrapping Paper

MOQ: 1000 kg

Material: DuPont Material

Specification: Custom sizes.

Design: Welcome custom logo and design. Welcome OEM.

Color: Full Color of CMYK,Pantone Color as customer requirements

Weight: Based on size & material,thickness

Delivery Time: 10-15 days after confirmed the final artwork and order

Product: Bi-component Non Woven Fabric Desiccant Packaging Material

MOQ: 1000 kg

Material: Bi-component Non Woven Fabric

Specification: Custom sizes.

Design: Welcome custom logo and design. Welcome OEM.

Color: Full Color of CMYK,Pantone Color as customer requirements

Weight: Based on size & material,thickness

Delivery Time: 10-15 days after confirmed the final artwork and order

Product: Spunbond Non Woven Fabric Custom Desiccant Packaging Material

MOQ: 1000 kg

Material: Spunbond Non Woven Fabric

Specification: Custom sizes.

Design: Welcome custom logo and design. Welcome OEM.

Color: Full Color of CMYK,Pantone Color as customer requirements

Weight: Based on size & material,thickness

Delivery Time: 10-15 days after confirmed the final artwork and order

When it comes to masks, all raw materials are polypropylene (PP, PP for short). Medical surgical masks generally have a multilayer structure, generally referred to as SMS structure.

The several layers of masks we often talk about are not stipulated by the national standard GB/T 32610. If it is a medical mask, it should have at least three layers, that is, what we call SMS (2s and 1m layers). At present, the top layer in China is five layers. Namely SMMMS (2s layer and 3m layer). It is not difficult to make masks. The difficult thing is to make SMMMS cloth. The price of an imported non-woven equipment is hundreds of millions. The most expensive medical non-woven equipment I have encountered One is 500 million yuan.

The S in this layer stands for spunbond fiber. The fiber diameter is relatively thick, about 20 microns (nm). The two layers of spunbond fiber mainly support the entire non-woven fabric(Mask Fabric Company) structure and have no significant effect on the barrier performance.

The most important thing inside the mask is the barrier layer or meltblown layer (M). The fiber diameter of the meltblown layer(Mask Filter On Sales) is relatively thin, about 2 microns (M), so it is only one-tenth of the diameter of the spunbond layer, which is essential to prevent bacteria and blood from entering the spunbond layer.

If the S spun bonding layer is too much, the mask is hard, and the spray layer M is too much, and breathing is difficult. Therefore, from the ease of use of the breathing mask to the evaluation of the effectiveness of the isolation mask, breathing is more difficult and the barrier effect is better. However, if M The layers form a film, they can hardly breathe, the virus is cut off, and people are dying, so this is a technical problem.

In order to better illustrate this point, we will compare the shape of the fiber and the hair in the spun layer M. As shown below, the diameter of the hair is one third, which is close to the spun bond layer. The fiber is 1/30 of the diameter of the hair, and the spray layer is close to the diameter of the M fiber. Of course, developers are also developing finer fibers to ensure better antibacterial barrier properties.

As mentioned above, the thinner M layer can prevent the entry of small particles such as bacteria. For example, N95(Melt Blown Factory) means that under normal circumstances, it can block 95% of small particles (0.3 microns). According to the national standard GB/T for medical respirators 19083, when the gas flow rate is 85L/min, the oil-free particle filtration efficiency mask meets the requirements of the following table:

From the above explanation, N95 is actually a 5-layer mask made of polypropylene non-woven fabric SMMMS, which can filter 95% of fine particles.