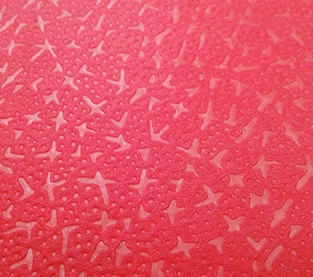

Product: ES Material Fiber Nonwoven Fabric For Packaging

Raw Material: PP+PE

Nonwoven Technology: thermal bonded

Dotted Design: dot or plain

Gram: 25 gsm - 30 gsm

Color: White

Specification: custom

Sample: Can be provided without charge, freight to be collect

Applications:

Medical(20-60gsm): face masks,diapers,bed sheets,curtains,pillow covers,sanitary,etc

Packaging(25-30gsm): tea bag, coffee bag/filter paper, dust-proof covers.etc

Product: ES Thermal Bonded Non Woven Fabric For Tea Bag

Raw Material: PP+PE

Nonwoven Technology: thermal bonded

Dotted Design: dot or plain

Gram: 25 gsm - 30 gsm

Color: White

Specification: custom

Sample: Can be provided without charge, freight to be collect

Applications:

Medical(20-60gsm): face masks,diapers,bed sheets,curtains,pillow covers,sanitary,etc

Packaging(25-30gsm): tea bag, coffee bag/filter paper, dust-proof covers.etc

Product: Composite Non Woven Paper Desiccant Packaging Material

MOQ: 1000 kg

Material: Composite Non Woven Paper

Specification: Custom sizes.

Design: Welcome custom logo and design. Welcome OEM.

Color: Full Color of CMYK,Pantone Color as customer requirements

Weight: Based on size & material,thickness

Delivery Time: 10-15 days after confirmed the final artwork and order

Product: Desiccant Wrapping Paper

MOQ: 1000 kg

Material: DuPont Material

Specification: Custom sizes.

Design: Welcome custom logo and design. Welcome OEM.

Color: Full Color of CMYK,Pantone Color as customer requirements

Weight: Based on size & material,thickness

Delivery Time: 10-15 days after confirmed the final artwork and order

Product: Bi-component Non Woven Fabric Desiccant Packaging Material

MOQ: 1000 kg

Material: Bi-component Non Woven Fabric

Specification: Custom sizes.

Design: Welcome custom logo and design. Welcome OEM.

Color: Full Color of CMYK,Pantone Color as customer requirements

Weight: Based on size & material,thickness

Delivery Time: 10-15 days after confirmed the final artwork and order

Product: Spunbond Non Woven Fabric Custom Desiccant Packaging Material

MOQ: 1000 kg

Material: Spunbond Non Woven Fabric

Specification: Custom sizes.

Design: Welcome custom logo and design. Welcome OEM.

Color: Full Color of CMYK,Pantone Color as customer requirements

Weight: Based on size & material,thickness

Delivery Time: 10-15 days after confirmed the final artwork and order

Customized new materials from Americhem

Americhem recently developed a new version of the mBrace soft additive in the nonwovens market. This is in addition to theinitial mBrace soft additive, which achieves the desired softness of the nonwoven fabric manufacturer(PP Nonwovens On Sales) by reducing the coefficient of friction orsliding. The new version currently being developed gives the feel of cotton textiles. The product's thermal stability allows manufacturers to produce softertouch materials without compromising other properties. At the same time, theproduct can be customized according to the manufacturer's specificr equirements, allowing the softness level to be set and the usage rate to bemore flexible. This helps the user ensure the best softness of the productwhile eliminating any effects of the machining process.

AGC develops finishing agent for medical non-woven fabric

Medical products such as surgical gowns,masks, drape and packaging must be able to repel liquids, oils and alcohol and quickly remove stains when washing. These properties are achieved by coatingthe nonwoven fabric(Polypropylene Spunbond Nonwovens Supplier) with a water repellency agent prior to manufacture into agarment. However, water repellents have had problems with sustainable time because they may decompose to form perfluorooctanoic acid (PFOA). To solve thisproblem, AGC Chemicals Americas developed AsahiGuard AG-E600, a high performance, PFOA-free water repellent with better environmental and biocompatibility characteristics.

BASF introduces waterborne acrylic adhesives

BASF has introduced a new, acrylic acrylic adhesive using Acronal 2434 for nonwovens that meet the high thermal stability requirements. Acronal waterborne acrylic and styrene acrylic dispersions areused as binders in high quality architectural coatings, adhesives, structuraland fiber bonding applications. Acronal redispersible powders are used asco-binders in dry mix mortars and improve their performance in a wide range of applications.

Eastman Microfibers achieve product diversity

Eastman has developed Cyphrex microfibers to meet the performance needs of increasingly demanding nonwoven applications,especially those manufacturers of wet and specialty papers that can be improvedin strength and uniformity. And benefit from reproducibility. Customized development also covers a variety of potential end uses, including but notlimited to filtration, packaging, high durability paper, wallpaper and batteries.

Exxon expands polymer field

Exxon Chemical has exited the new low viscosity Vistanmaxx high performance polymer for sanitary and assembly hotmelt applications.

Vistamaxx high performance polymers enable companies to develop innovative solutions that improve product performance and productivity. It also has the potential for sustainable development, reducing the packaging film, reducing the amount of material used, and reducing the thickness of the hard package to increase product strength to avoid damage orwaste. At the same time, he also achieved lower processing temperatures,thereby reducing energy consumption.

Omnova provides adhesives and finishes

For nonwovens, many factors affect fiber selection, fabric forming and fixing processes, including process efficiency,product performance, application requirements, consumer demand, and cost ofuse. Omnova's polymer recombination and finishing/surface treatments providegreater flexibility in the timing of these important processes. For volatileraw materials currently in use, nonwovens manufacturers(PP Non Woven Cloth Manufacturer) are looking for aflexible combination of different fibers and polymers. In spunlace wipes, theraw material mixture usually consists of 50% absorbent fiber (polyester or polypropylene), depending on the price of the raw material. Currently, the percentageof viscose is reduced in rain-wiping products. This will have a negative impacton absorptive capacity and softness.

In addition, OMNOVA's anti-aging agents and elastomer modifiers are used in rubber components for elastic waistbands andother stretchable materials to impart elasticity and aging resistance.