Product: ES Material Fiber Nonwoven Fabric For Packaging

Raw Material: PP+PE

Nonwoven Technology: thermal bonded

Dotted Design: dot or plain

Gram: 25 gsm - 30 gsm

Color: White

Specification: custom

Sample: Can be provided without charge, freight to be collect

Applications:

Medical(20-60gsm): face masks,diapers,bed sheets,curtains,pillow covers,sanitary,etc

Packaging(25-30gsm): tea bag, coffee bag/filter paper, dust-proof covers.etc

Product: ES Thermal Bonded Non Woven Fabric For Tea Bag

Raw Material: PP+PE

Nonwoven Technology: thermal bonded

Dotted Design: dot or plain

Gram: 25 gsm - 30 gsm

Color: White

Specification: custom

Sample: Can be provided without charge, freight to be collect

Applications:

Medical(20-60gsm): face masks,diapers,bed sheets,curtains,pillow covers,sanitary,etc

Packaging(25-30gsm): tea bag, coffee bag/filter paper, dust-proof covers.etc

Product: Composite Non Woven Paper Desiccant Packaging Material

MOQ: 1000 kg

Material: Composite Non Woven Paper

Specification: Custom sizes.

Design: Welcome custom logo and design. Welcome OEM.

Color: Full Color of CMYK,Pantone Color as customer requirements

Weight: Based on size & material,thickness

Delivery Time: 10-15 days after confirmed the final artwork and order

Product: Desiccant Wrapping Paper

MOQ: 1000 kg

Material: DuPont Material

Specification: Custom sizes.

Design: Welcome custom logo and design. Welcome OEM.

Color: Full Color of CMYK,Pantone Color as customer requirements

Weight: Based on size & material,thickness

Delivery Time: 10-15 days after confirmed the final artwork and order

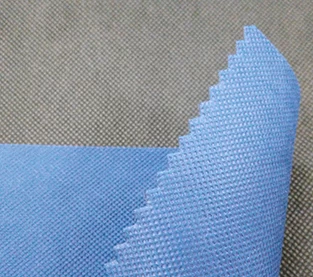

Product: Bi-component Non Woven Fabric Desiccant Packaging Material

MOQ: 1000 kg

Material: Bi-component Non Woven Fabric

Specification: Custom sizes.

Design: Welcome custom logo and design. Welcome OEM.

Color: Full Color of CMYK,Pantone Color as customer requirements

Weight: Based on size & material,thickness

Delivery Time: 10-15 days after confirmed the final artwork and order

Product: Spunbond Non Woven Fabric Custom Desiccant Packaging Material

MOQ: 1000 kg

Material: Spunbond Non Woven Fabric

Specification: Custom sizes.

Design: Welcome custom logo and design. Welcome OEM.

Color: Full Color of CMYK,Pantone Color as customer requirements

Weight: Based on size & material,thickness

Delivery Time: 10-15 days after confirmed the final artwork and order

Polylactic acid(PLA Non Woven Fabric Factory), a biopolymer material developed by the School of Materials and Science Engineering of Tongji University, recently won an Innovation Award at the Industry Fair. This kind of polylactic acid, commonly known as "corn plastic", is considered to be the terminator of "white pollution" caused by traditional chemical plastics.

The raw material of polylactic acid(Degradable Nonwovens On Sales) is not only corn, but many other crops can be used to extract lactic acid. Therefore, it is more appropriate to refer to polylactic acid as "biomass plastic".

Today, with the depletion of various petrochemical resources such as oil and coal, the development and application of biological resources have attracted the attention of scientists around the world, and have also driven the vigorous development of the biomass industry. This emerging industry uses bio-chemical methods to produce fuels, energy, and biomass materials (including plastics, fibers, etc.) using renewable or recycled organic materials such as crops and livestock manure.

According to professionals, only one US company in the world can produce polylactic acid on a large scale. The company's production process uses the "two-step method", the production cost is high, and the price per ton is about 3,000 US dollars. Although the price is high, it can't stop the demand of the market, especially in developed countries.

In China, such high prices are clearly unacceptable in the market. How to improve the production cost through technical improvement, so as to produce a cheap and good polylactic acid(Environmentally Friendly Non-woven Wholesale) has become the focus of research. At the same time, the subject of the School of Materials and Science Engineering of Tongji University was also listed as one of the first batch of 29 industrialization projects in Shanghai.

After 8 years of research and 1 year of industrialization, Tongji University's School of Materials and Science Engineering finally researched the advanced technology of “one-step method” for the preparation of polylactic acid. Through the organic combination of bioengineering technology and polymer synthesis technology, the “one-step method” can synthesize lactic acid extracted from corn into polylactic acid particles, and the production cost is greatly reduced. Therefore, polylactic acid has the conditions for promotion and application in China.