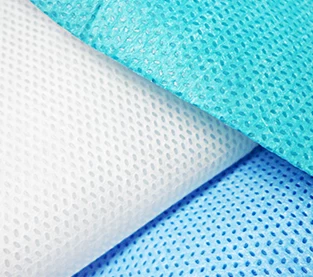

Product: ES Material Fiber Nonwoven Fabric For Packaging

Raw Material: PP+PE

Nonwoven Technology: thermal bonded

Dotted Design: dot or plain

Gram: 25 gsm - 30 gsm

Color: White

Specification: custom

Sample: Can be provided without charge, freight to be collect

Applications:

Medical(20-60gsm): face masks,diapers,bed sheets,curtains,pillow covers,sanitary,etc

Packaging(25-30gsm): tea bag, coffee bag/filter paper, dust-proof covers.etc

Product: ES Thermal Bonded Non Woven Fabric For Tea Bag

Raw Material: PP+PE

Nonwoven Technology: thermal bonded

Dotted Design: dot or plain

Gram: 25 gsm - 30 gsm

Color: White

Specification: custom

Sample: Can be provided without charge, freight to be collect

Applications:

Medical(20-60gsm): face masks,diapers,bed sheets,curtains,pillow covers,sanitary,etc

Packaging(25-30gsm): tea bag, coffee bag/filter paper, dust-proof covers.etc

Product: Composite Non Woven Paper Desiccant Packaging Material

MOQ: 1000 kg

Material: Composite Non Woven Paper

Specification: Custom sizes.

Design: Welcome custom logo and design. Welcome OEM.

Color: Full Color of CMYK,Pantone Color as customer requirements

Weight: Based on size & material,thickness

Delivery Time: 10-15 days after confirmed the final artwork and order

Product: Desiccant Wrapping Paper

MOQ: 1000 kg

Material: DuPont Material

Specification: Custom sizes.

Design: Welcome custom logo and design. Welcome OEM.

Color: Full Color of CMYK,Pantone Color as customer requirements

Weight: Based on size & material,thickness

Delivery Time: 10-15 days after confirmed the final artwork and order

Product: Bi-component Non Woven Fabric Desiccant Packaging Material

MOQ: 1000 kg

Material: Bi-component Non Woven Fabric

Specification: Custom sizes.

Design: Welcome custom logo and design. Welcome OEM.

Color: Full Color of CMYK,Pantone Color as customer requirements

Weight: Based on size & material,thickness

Delivery Time: 10-15 days after confirmed the final artwork and order

Product: Spunbond Non Woven Fabric Custom Desiccant Packaging Material

MOQ: 1000 kg

Material: Spunbond Non Woven Fabric

Specification: Custom sizes.

Design: Welcome custom logo and design. Welcome OEM.

Color: Full Color of CMYK,Pantone Color as customer requirements

Weight: Based on size & material,thickness

Delivery Time: 10-15 days after confirmed the final artwork and order

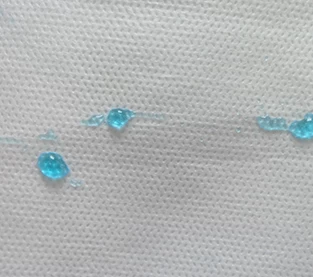

The most important application of medical non-woven shielding materials is medical non-woven protective clothing, and now the demand is increasing. Below we will introduce the current technical research and development degree of medical non-woven medical(SMS Nonwovens Company) non-woven shielding materials.

A new generation of biomedical materials, key technologies of bio-based textile materials, high-efficiency ecological dyeing and finishing technology and application of textile materials as the development focus, and further enhance the overall competitiveness of the industry, in the "Special Plan for Scientific and Technological Innovation in the "13th Five-Year Plan" Materials Field".

The annual output of 8000 tons of demonstration line, the quality of medical non-woven fabric(Non Woven Meltblown Fabric Wholesale) shielding materials produced by the industry meets the requirements of industry standards. The project has built a 3.2-meter wide, mechanical speed of 500 m / min, 5 die configuration. The Ministry of Science and Technology has implemented the National Science and Technology Support Program for the “Research and Development and Industrialization of Non-woven Shielding Materials for Medical Hygiene”, which has been implemented for more than three years. In order to implement the "National Medium- and Long-Term Science and Technology Development Plan (2006-2020)", the "Twelfth Five-Year Plan" period.

China's medical and health textiles(PP Meltblown Fabric Supplier) will grow at a rate of 10%-15%. The application of the European and American markets is close to saturation, and China's current application is still in its infancy, which has huge market potential. Global medical and sanitary textiles are growing at a rate of 5%-10%, according to the report of China Industrial Textiles Industry Association “Analysis of the Economic Operation Characteristics of China's Industrial Textile Industry in 2015”. In order to prevent indirect infection and cross-infection of viruses caused by bacterial penetration, the performance requirements of medical shielding materials are getting higher and higher, and the use occasions are also increasing.