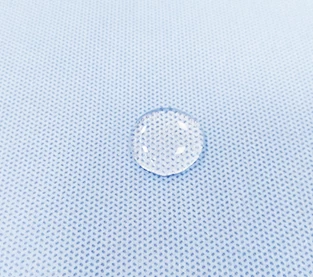

Product: ES Material Fiber Nonwoven Fabric For Packaging

Raw Material: PP+PE

Nonwoven Technology: thermal bonded

Dotted Design: dot or plain

Gram: 25 gsm - 30 gsm

Color: White

Specification: custom

Sample: Can be provided without charge, freight to be collect

Applications:

Medical(20-60gsm): face masks,diapers,bed sheets,curtains,pillow covers,sanitary,etc

Packaging(25-30gsm): tea bag, coffee bag/filter paper, dust-proof covers.etc

Product: ES Thermal Bonded Non Woven Fabric For Tea Bag

Raw Material: PP+PE

Nonwoven Technology: thermal bonded

Dotted Design: dot or plain

Gram: 25 gsm - 30 gsm

Color: White

Specification: custom

Sample: Can be provided without charge, freight to be collect

Applications:

Medical(20-60gsm): face masks,diapers,bed sheets,curtains,pillow covers,sanitary,etc

Packaging(25-30gsm): tea bag, coffee bag/filter paper, dust-proof covers.etc

Product: Composite Non Woven Paper Desiccant Packaging Material

MOQ: 1000 kg

Material: Composite Non Woven Paper

Specification: Custom sizes.

Design: Welcome custom logo and design. Welcome OEM.

Color: Full Color of CMYK,Pantone Color as customer requirements

Weight: Based on size & material,thickness

Delivery Time: 10-15 days after confirmed the final artwork and order

Product: Desiccant Wrapping Paper

MOQ: 1000 kg

Material: DuPont Material

Specification: Custom sizes.

Design: Welcome custom logo and design. Welcome OEM.

Color: Full Color of CMYK,Pantone Color as customer requirements

Weight: Based on size & material,thickness

Delivery Time: 10-15 days after confirmed the final artwork and order

Product: Bi-component Non Woven Fabric Desiccant Packaging Material

MOQ: 1000 kg

Material: Bi-component Non Woven Fabric

Specification: Custom sizes.

Design: Welcome custom logo and design. Welcome OEM.

Color: Full Color of CMYK,Pantone Color as customer requirements

Weight: Based on size & material,thickness

Delivery Time: 10-15 days after confirmed the final artwork and order

Product: Spunbond Non Woven Fabric Custom Desiccant Packaging Material

MOQ: 1000 kg

Material: Spunbond Non Woven Fabric

Specification: Custom sizes.

Design: Welcome custom logo and design. Welcome OEM.

Color: Full Color of CMYK,Pantone Color as customer requirements

Weight: Based on size & material,thickness

Delivery Time: 10-15 days after confirmed the final artwork and order

Fiber

The fibers used in medical non-woven fabrics(Medical SMS Nonwovens Wholesale) can be divided into natural and synthetic categories. The natural fibers used are wood pulp, cotton and rayon. Wood pulp is used because of its obvious absorbency, large volume and low cost. Cotton and rayon are better used directly on the wound. They have good absorbency and can be made into high-quality non-woven fabrics(Waterproof Nonwoven Fabric Manufacturer).

The reasons why natural fibers make high-quality medical non-woven fabrics(China SMS Non Woven Fabric Factory) are:

1. They highly absorb exudate and blood

2. Excellent breathability

3. Good aesthetic characteristics

4. Easy to clean and can be disinfected

5. Excellent dimensional stability and high operating temperature? 175 degrees Celsius

6. Biodegradable

7. Excellent drape and compliance

8. Good heat resistance

9. Excellent water retention capacity

10. Non-allergenic and non-irritating fiber

The most commonly used synthetic fiber in this application is: polypropylene, which has excellent rheological properties, needs hydrophobicity in some systems that require barrier properties, low cost, and is widely used for thermal bonding and increased functionality. Split fiber, and high-strength polyester, mechanical properties and easy sterilization are essential. Synthetic fiber also considers the product's strength, solvent resistance, static dissipation and many other desirable properties.

Properties of synthetic fibers required in many applications:

1. Hydrophobicity: can be used as a barrier fabric

2. Easy to process

3. Cost-effective

4. High strength, low density, better performance

5. Easy to handle, no danger