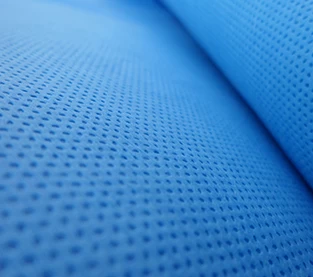

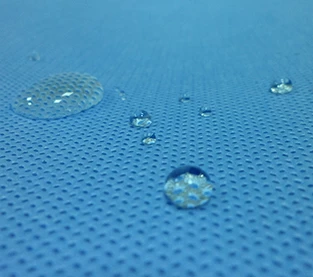

Product: ES Material Fiber Nonwoven Fabric For Packaging

Raw Material: PP+PE

Nonwoven Technology: thermal bonded

Dotted Design: dot or plain

Gram: 25 gsm - 30 gsm

Color: White

Specification: custom

Sample: Can be provided without charge, freight to be collect

Applications:

Medical(20-60gsm): face masks,diapers,bed sheets,curtains,pillow covers,sanitary,etc

Packaging(25-30gsm): tea bag, coffee bag/filter paper, dust-proof covers.etc

Product: ES Thermal Bonded Non Woven Fabric For Tea Bag

Raw Material: PP+PE

Nonwoven Technology: thermal bonded

Dotted Design: dot or plain

Gram: 25 gsm - 30 gsm

Color: White

Specification: custom

Sample: Can be provided without charge, freight to be collect

Applications:

Medical(20-60gsm): face masks,diapers,bed sheets,curtains,pillow covers,sanitary,etc

Packaging(25-30gsm): tea bag, coffee bag/filter paper, dust-proof covers.etc

Product: Composite Non Woven Paper Desiccant Packaging Material

MOQ: 1000 kg

Material: Composite Non Woven Paper

Specification: Custom sizes.

Design: Welcome custom logo and design. Welcome OEM.

Color: Full Color of CMYK,Pantone Color as customer requirements

Weight: Based on size & material,thickness

Delivery Time: 10-15 days after confirmed the final artwork and order

Product: Desiccant Wrapping Paper

MOQ: 1000 kg

Material: DuPont Material

Specification: Custom sizes.

Design: Welcome custom logo and design. Welcome OEM.

Color: Full Color of CMYK,Pantone Color as customer requirements

Weight: Based on size & material,thickness

Delivery Time: 10-15 days after confirmed the final artwork and order

Product: Bi-component Non Woven Fabric Desiccant Packaging Material

MOQ: 1000 kg

Material: Bi-component Non Woven Fabric

Specification: Custom sizes.

Design: Welcome custom logo and design. Welcome OEM.

Color: Full Color of CMYK,Pantone Color as customer requirements

Weight: Based on size & material,thickness

Delivery Time: 10-15 days after confirmed the final artwork and order

Product: Spunbond Non Woven Fabric Custom Desiccant Packaging Material

MOQ: 1000 kg

Material: Spunbond Non Woven Fabric

Specification: Custom sizes.

Design: Welcome custom logo and design. Welcome OEM.

Color: Full Color of CMYK,Pantone Color as customer requirements

Weight: Based on size & material,thickness

Delivery Time: 10-15 days after confirmed the final artwork and order

Surgical Drapes: Mainly used to protect patients from infection and reduce the risk of infection at the surgical site.

Surgical film: For surgery with a long operation time and a high risk of infection, to protect the sterile surface of the skin for a long time.

Surgical gowns, masks, hats, surgical gloves: mainly used to protect medical staff and avoid cross-infection.

Cloth: Wrap the surgical supplies for disinfection and sterilization.

Hand towel: Preoperative surgical hand washing.

All factors affecting the growth of man-made fibers can have a certain impact on textiles made from rayon, which has the greatest impact on non-woven textiles. The population growth factor has less impact on non-woven fabrics(SMS Nonwovens On Sales) than other textiles used in apparel. But if the important application of non-woven fabrics in baby diapers is taken into account, population growth is also an important factor. The replacement of the natural fiber portion has a greater influence on the textile, but has little effect on the nonwoven fabric because the production of the nonwoven fabric is basically dependent on the rayon.

The commercial development of man-made fibers and the professional application of non-woven fabrics(SMS Nonwovens Factory): The trade in micro-fibers, composite fibers, biodegradable fibers and new polyester fibers has increased due to the establishment of international economic treaties. This has a great influence on non-woven fabrics, but has little effect on apparel and knitted textiles. Replacing textiles and other supplies: This includes being replaced by non-woven textiles, knitted textiles, plastic films, polyurea foams, wood pulp, leather, and the like. This is determined by the cost and performance requirements of the product. Introducing new, more economical and efficient production processes: the use of polymers to make a variety of articles, the application of competitive new nonwovens and the introduction of specialty fibers and nonwoven textile additives.