Product: ES Material Fiber Nonwoven Fabric For Packaging

Raw Material: PP+PE

Nonwoven Technology: thermal bonded

Dotted Design: dot or plain

Gram: 25 gsm - 30 gsm

Color: White

Specification: custom

Sample: Can be provided without charge, freight to be collect

Applications:

Medical(20-60gsm): face masks,diapers,bed sheets,curtains,pillow covers,sanitary,etc

Packaging(25-30gsm): tea bag, coffee bag/filter paper, dust-proof covers.etc

Product: ES Thermal Bonded Non Woven Fabric For Tea Bag

Raw Material: PP+PE

Nonwoven Technology: thermal bonded

Dotted Design: dot or plain

Gram: 25 gsm - 30 gsm

Color: White

Specification: custom

Sample: Can be provided without charge, freight to be collect

Applications:

Medical(20-60gsm): face masks,diapers,bed sheets,curtains,pillow covers,sanitary,etc

Packaging(25-30gsm): tea bag, coffee bag/filter paper, dust-proof covers.etc

Product: Composite Non Woven Paper Desiccant Packaging Material

MOQ: 1000 kg

Material: Composite Non Woven Paper

Specification: Custom sizes.

Design: Welcome custom logo and design. Welcome OEM.

Color: Full Color of CMYK,Pantone Color as customer requirements

Weight: Based on size & material,thickness

Delivery Time: 10-15 days after confirmed the final artwork and order

Product: Desiccant Wrapping Paper

MOQ: 1000 kg

Material: DuPont Material

Specification: Custom sizes.

Design: Welcome custom logo and design. Welcome OEM.

Color: Full Color of CMYK,Pantone Color as customer requirements

Weight: Based on size & material,thickness

Delivery Time: 10-15 days after confirmed the final artwork and order

Product: Bi-component Non Woven Fabric Desiccant Packaging Material

MOQ: 1000 kg

Material: Bi-component Non Woven Fabric

Specification: Custom sizes.

Design: Welcome custom logo and design. Welcome OEM.

Color: Full Color of CMYK,Pantone Color as customer requirements

Weight: Based on size & material,thickness

Delivery Time: 10-15 days after confirmed the final artwork and order

Product: Spunbond Non Woven Fabric Custom Desiccant Packaging Material

MOQ: 1000 kg

Material: Spunbond Non Woven Fabric

Specification: Custom sizes.

Design: Welcome custom logo and design. Welcome OEM.

Color: Full Color of CMYK,Pantone Color as customer requirements

Weight: Based on size & material,thickness

Delivery Time: 10-15 days after confirmed the final artwork and order

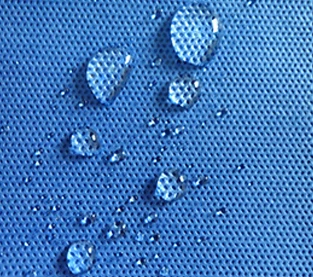

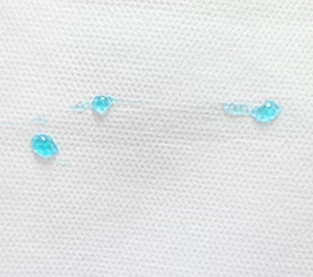

Surgical gowns and surgical gowns are equally safe for patients and doctors because microorganisms are also carried in when the fluid penetrates the material, so the surgical gown must be able to prevent the penetration of liquids and the accompanying bacteria. Studying the factors affecting the hydrostatic pressure of the spunmelt nonwoven fabric can help to find ways to improve the barrier properties of SMS non-woven fabrics(China SMS Non-woven Roll Factory), improve production efficiency, and stabilize and gradually improve the quality of non-woven fabrics(PP SMS Nonwovens Manufacturer) for medical protection. The influence of various process parameters of melt blowing on the anti-hydrostatic performance of the product during the SMS process mainly includes: raw material, melt blowing ratio, screw die temperature, hot air temperature and air volume, receiving distance, machine state and so on.

There are many indicators involved in the barrier properties of surgical gowns to water, such as anti-static water pressure, spray test, water level, etc. The most common one is anti-hydrostatic pressure. Anti-hydrostatic pressure refers to the ability of the test material to resist the slow rise of water pressure. In the test methods of various systems, the index is judged according to the test area, the water pressure rising speed and the end position determined by several water drops. The larger the amount, the better the barrier properties of the material to water. The SMS non-woven fabric(Spunbond Meltblown Spunbond Fabric Wholesale) has a dense melt-blown layer in the middle, and the fiber has a small linear density, which is basically ultra-fine fiber, which can reach 0.01 dtex~0.05 dtex, which is about 1% of the linear density of ordinary spunbond fiber. The fibers of the meltblown web are very fine and the web is very uniform. When the liquid comes into contact with it, the surface tension liquid is not easily penetrated, and the void formed by the connection between the ultrafine fibers is relatively small, so dust and bacteria are blocked, and the surgical gown is approached to "absolutely clean" effect.