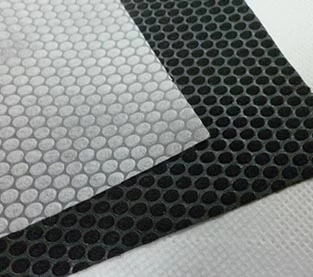

Product: ES Material Fiber Nonwoven Fabric For Packaging

Raw Material: PP+PE

Nonwoven Technology: thermal bonded

Dotted Design: dot or plain

Gram: 25 gsm - 30 gsm

Color: White

Specification: custom

Sample: Can be provided without charge, freight to be collect

Applications:

Medical(20-60gsm): face masks,diapers,bed sheets,curtains,pillow covers,sanitary,etc

Packaging(25-30gsm): tea bag, coffee bag/filter paper, dust-proof covers.etc

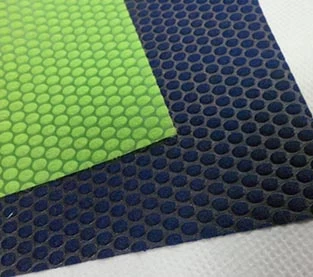

Product: ES Thermal Bonded Non Woven Fabric For Tea Bag

Raw Material: PP+PE

Nonwoven Technology: thermal bonded

Dotted Design: dot or plain

Gram: 25 gsm - 30 gsm

Color: White

Specification: custom

Sample: Can be provided without charge, freight to be collect

Applications:

Medical(20-60gsm): face masks,diapers,bed sheets,curtains,pillow covers,sanitary,etc

Packaging(25-30gsm): tea bag, coffee bag/filter paper, dust-proof covers.etc

Product: Composite Non Woven Paper Desiccant Packaging Material

MOQ: 1000 kg

Material: Composite Non Woven Paper

Specification: Custom sizes.

Design: Welcome custom logo and design. Welcome OEM.

Color: Full Color of CMYK,Pantone Color as customer requirements

Weight: Based on size & material,thickness

Delivery Time: 10-15 days after confirmed the final artwork and order

Product: Desiccant Wrapping Paper

MOQ: 1000 kg

Material: DuPont Material

Specification: Custom sizes.

Design: Welcome custom logo and design. Welcome OEM.

Color: Full Color of CMYK,Pantone Color as customer requirements

Weight: Based on size & material,thickness

Delivery Time: 10-15 days after confirmed the final artwork and order

Product: Bi-component Non Woven Fabric Desiccant Packaging Material

MOQ: 1000 kg

Material: Bi-component Non Woven Fabric

Specification: Custom sizes.

Design: Welcome custom logo and design. Welcome OEM.

Color: Full Color of CMYK,Pantone Color as customer requirements

Weight: Based on size & material,thickness

Delivery Time: 10-15 days after confirmed the final artwork and order

Product: Spunbond Non Woven Fabric Custom Desiccant Packaging Material

MOQ: 1000 kg

Material: Spunbond Non Woven Fabric

Specification: Custom sizes.

Design: Welcome custom logo and design. Welcome OEM.

Color: Full Color of CMYK,Pantone Color as customer requirements

Weight: Based on size & material,thickness

Delivery Time: 10-15 days after confirmed the final artwork and order

North America is an important producer and consumer of the world's nonwovens industry, especially the United States. It is also an important source of technological innovation and funding for the nonwovens industry and is a leader in the global nonwovens industry. DAVE Rousse, President of the American Nonwovens Association, attends the China International Nonwovens Conference every year and introduces us to the latest developments in the North American nonwovens market. The following is an adaptation of Mr. DAVE Rousse's presentation.

In recent years, the strong growth of the US economy has brought about tremendous growth in the nonwovens industry. In 2017, there will be approximately 800 non-woven production lines in North America with a capacity of nearly 5 million tons. According to the process, 30% of the production capacity is spinning and smelting, 70% of the production capacity is short fiber products, dry non-woven fabrics account for 43%, wet methods account for 22%, and air flow into the network accounts for 5%; In view, 89% of production capacity is concentrated in the United States, Mexico is 7%, and Canada is 4%.

From 2016 to 2018, a total of 61 non-woven production lines were added in North America. Among them, the number of needle-punching lines is the largest, totaling 25, with a capacity of 218,000 tons; 12 thermal bonding production lines with an additional capacity of about 60,000 tons; and nine spinning and smelting production lines with an additional capacity of 125,000 tons. From the point of view of terminal applications, transportation is the largest market, and 29 series of products serve this field. Filtration and furniture are other important markets, with 17 production lines in each market; 12 production lines for absorbent hygienic materials(China Nonwovens Products Manufacturer) and 8 production lines for wiping materials. Seventy-five percent of the new production lines target two or more application markets.

From an application market perspective, absorbent hygienic materials, filters, vehicles and buildings are the largest applications of North American nonwovens(Disposable Non-Woven Products Wholesale), each accounting for 14% of total production, wiping 11%, furniture 10%, 6% medical and 5 % geotechnical engineering. According to INDA, automotive nonwovens(Non Woven Products Company) will become the fastest growing market in the future, with an increase of more than 8%. The growth of nonwoven fabrics for automobiles is mainly due to the expansion of the application range of nonwoven fabrics in automobiles because of their superior performance. On the other hand, the growth of automobile production and consumption in the United States over the past seven years has led to an increase in the size of automobiles. Although absorbent hygienic materials are currently the largest application, the application of nonwovens in this field shows a downward trend from 2011 to 2016, but the application is expected to increase from 2016 to 2021, but the growth rate is lower. Level. . From 2018 to 2022, North American non-woven fabric production is expected to grow at an average annual rate of 3.6%, with an average annual growth of 152,000 tons.

As for the challenges facing the US nonwovens industry, Mr. DAVE believes that the dispersibility of wipes and the contamination of disposable hygiene products are the future focus of the industry. The challenge of washable wipes is primarily due to confusion between product identification and consumer “cleanable” and “non-cleanable” products, leading to media litigation and follow-up reporting. As a result, INDA and EDANA updated the new version of the GD4 guide to evaluate washable products, develop a guide to cleanable labels, and establish a responsible cleansing alliance. The problem of one-time product pollution has gradually entered the public eye, especially marine garbage, polypropylene and polyester products are difficult to degrade in the environment. Regarding the issues of separate documents issued by INDA and EDANA, the problem is clarified, and it is hoped to realize industrialization through material innovation. Resolve recyclable, biodegradable non-woven products to reduce environmental impact.