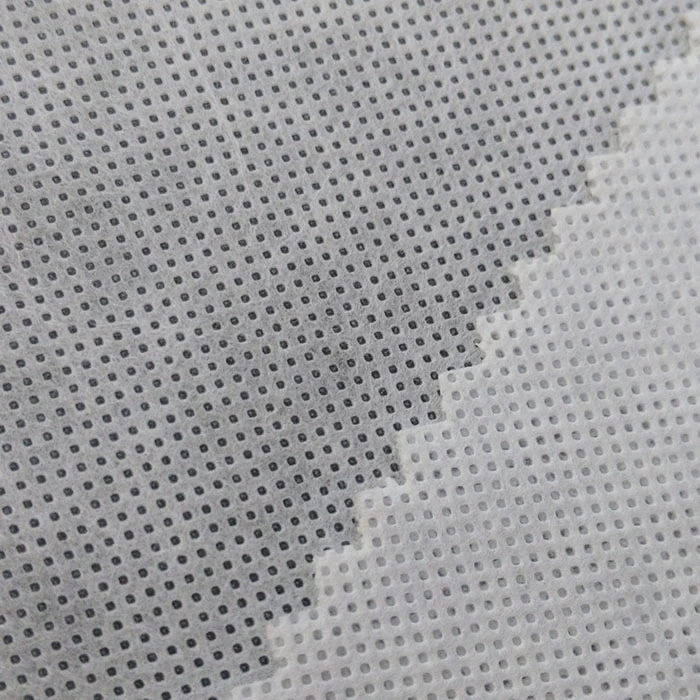

Product: ES Material Fiber Nonwoven Fabric For Packaging

Raw Material: PP+PE

Nonwoven Technology: thermal bonded

Dotted Design: dot or plain

Gram: 25 gsm - 30 gsm

Color: White

Specification: custom

Sample: Can be provided without charge, freight to be collect

Applications:

Medical(20-60gsm): face masks,diapers,bed sheets,curtains,pillow covers,sanitary,etc

Packaging(25-30gsm): tea bag, coffee bag/filter paper, dust-proof covers.etc

Product: ES Thermal Bonded Non Woven Fabric For Tea Bag

Raw Material: PP+PE

Nonwoven Technology: thermal bonded

Dotted Design: dot or plain

Gram: 25 gsm - 30 gsm

Color: White

Specification: custom

Sample: Can be provided without charge, freight to be collect

Applications:

Medical(20-60gsm): face masks,diapers,bed sheets,curtains,pillow covers,sanitary,etc

Packaging(25-30gsm): tea bag, coffee bag/filter paper, dust-proof covers.etc

Product: Composite Non Woven Paper Desiccant Packaging Material

MOQ: 1000 kg

Material: Composite Non Woven Paper

Specification: Custom sizes.

Design: Welcome custom logo and design. Welcome OEM.

Color: Full Color of CMYK,Pantone Color as customer requirements

Weight: Based on size & material,thickness

Delivery Time: 10-15 days after confirmed the final artwork and order

Product: Desiccant Wrapping Paper

MOQ: 1000 kg

Material: DuPont Material

Specification: Custom sizes.

Design: Welcome custom logo and design. Welcome OEM.

Color: Full Color of CMYK,Pantone Color as customer requirements

Weight: Based on size & material,thickness

Delivery Time: 10-15 days after confirmed the final artwork and order

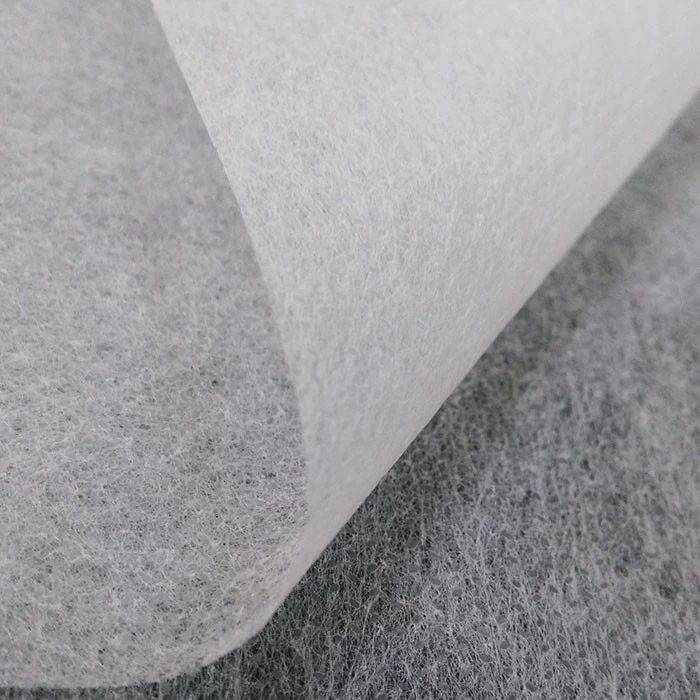

Product: Bi-component Non Woven Fabric Desiccant Packaging Material

MOQ: 1000 kg

Material: Bi-component Non Woven Fabric

Specification: Custom sizes.

Design: Welcome custom logo and design. Welcome OEM.

Color: Full Color of CMYK,Pantone Color as customer requirements

Weight: Based on size & material,thickness

Delivery Time: 10-15 days after confirmed the final artwork and order

Product: Spunbond Non Woven Fabric Custom Desiccant Packaging Material

MOQ: 1000 kg

Material: Spunbond Non Woven Fabric

Specification: Custom sizes.

Design: Welcome custom logo and design. Welcome OEM.

Color: Full Color of CMYK,Pantone Color as customer requirements

Weight: Based on size & material,thickness

Delivery Time: 10-15 days after confirmed the final artwork and order

The PP spunbond fabric is widely used in our daily life now.

It can be used for many different files,such as shopping bag,mulch film,face mask,protecting clothing,disposible bed sheets,Diaper, flower packing material,etc.

There is S/SS pp spunbond fabric (China polypropylene non woven material vendor) available for the clients to choose.

What is the difference between these 2 kinds fabric?

1.the softness

The S spunbond fabric often used in packing file,

the SS spunbond fabric used in hygiene material.

For the pp spunbond production machine ,the S TYPE machine will make the nonwoven fabric harder to meet the demand for packing.

And the SS machine will make the fabric softer ,it will be more suitable for the hygiene products (sanitaty pad/daiper).

But the S spunbond fabric also can add a certain softening masterbatch to improve the softness.

2.the evenness

The evenness is the stability of the gram for per square meter of the fabric.

It is hard to distinguish by the eyes.

Usually we need to check the gram by the equipment.

Usually there is 5% - 8% tolerance for the S pp spunbond nonwoven gram per square meter.

And for SS spunbond fabric (PP spunbond non woven material wholesaler), the tolerance will be approx 3% -6% .

So the evenness for SS is better than S spunbond fabric.

3.different spinneret for the fabric machine

Essentially, The S spunbond fabric is made by 1 spinneret machine.

The SS spunbond fabric is made by 2 spinnerets machine.

More spinnerets to spin the filament, the fabric will be with better evenness.

In conclusion, I think there is not big difference between S (China ss non woven fabric wholesale )and SS spunbond fabric.

We should pay more attention to the hygienic standard,tensile strength,component of the raw material between S and SS spunbond fabric.