Product: ES Material Fiber Nonwoven Fabric For Packaging

Raw Material: PP+PE

Nonwoven Technology: thermal bonded

Dotted Design: dot or plain

Gram: 25 gsm - 30 gsm

Color: White

Specification: custom

Sample: Can be provided without charge, freight to be collect

Applications:

Medical(20-60gsm): face masks,diapers,bed sheets,curtains,pillow covers,sanitary,etc

Packaging(25-30gsm): tea bag, coffee bag/filter paper, dust-proof covers.etc

Product: ES Thermal Bonded Non Woven Fabric For Tea Bag

Raw Material: PP+PE

Nonwoven Technology: thermal bonded

Dotted Design: dot or plain

Gram: 25 gsm - 30 gsm

Color: White

Specification: custom

Sample: Can be provided without charge, freight to be collect

Applications:

Medical(20-60gsm): face masks,diapers,bed sheets,curtains,pillow covers,sanitary,etc

Packaging(25-30gsm): tea bag, coffee bag/filter paper, dust-proof covers.etc

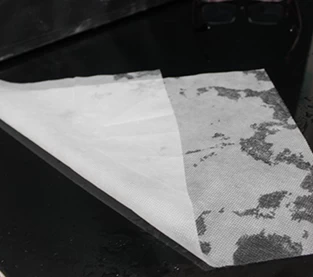

Product: Composite Non Woven Paper Desiccant Packaging Material

MOQ: 1000 kg

Material: Composite Non Woven Paper

Specification: Custom sizes.

Design: Welcome custom logo and design. Welcome OEM.

Color: Full Color of CMYK,Pantone Color as customer requirements

Weight: Based on size & material,thickness

Delivery Time: 10-15 days after confirmed the final artwork and order

Product: Desiccant Wrapping Paper

MOQ: 1000 kg

Material: DuPont Material

Specification: Custom sizes.

Design: Welcome custom logo and design. Welcome OEM.

Color: Full Color of CMYK,Pantone Color as customer requirements

Weight: Based on size & material,thickness

Delivery Time: 10-15 days after confirmed the final artwork and order

Product: Bi-component Non Woven Fabric Desiccant Packaging Material

MOQ: 1000 kg

Material: Bi-component Non Woven Fabric

Specification: Custom sizes.

Design: Welcome custom logo and design. Welcome OEM.

Color: Full Color of CMYK,Pantone Color as customer requirements

Weight: Based on size & material,thickness

Delivery Time: 10-15 days after confirmed the final artwork and order

Product: Spunbond Non Woven Fabric Custom Desiccant Packaging Material

MOQ: 1000 kg

Material: Spunbond Non Woven Fabric

Specification: Custom sizes.

Design: Welcome custom logo and design. Welcome OEM.

Color: Full Color of CMYK,Pantone Color as customer requirements

Weight: Based on size & material,thickness

Delivery Time: 10-15 days after confirmed the final artwork and order

The filter material industry has a great demand for product innovation. New legislation and increasingly serious environmental problems will promote the research and development of new products. Filter materials must be updated to maintain the efficiency and performance requirements of the downstream market.

The combination of nanotechnology and filter materials(China Filter Material Company) is a hotspot of research and development. Advances in melt-blown nonwoven technology have made it possible to produce melt-blown fibers that are close to the nanometer level. In addition, meltblown nonwoven products have the advantages of low cost, high efficiency, solvent-free, simple process flow, etc., and have become one of the most competitive materials in the high-efficiency filtration market. Compared with spunbond, needle punched and wet-laid non-woven filter materials, melt-blown non-woven filter materials are more fluffy and have better pollution control capabilities. They are particularly widely used in the field of high-efficiency fine filtration. At present, meltblown nonwoven filter media has penetrated into various application fields of liquid and air filtration, and the market is expected to usher in rapid growth in the future.

The material is extruded from molten polymer fibers that pass through a die and can contain up to 40 holes per inch. The fiber is then drawn, cooled and further processed to meet the requirements of the end use. Because of its smooth matrix, large surface area, moderate strength, it can be used for filtration products in food and beverage, chemical, mining and other fields.

At present, the world's leading filter material manufacturers(Filtration Nonwovens Factory) have launched high-efficiency filtration products using melt-blown technology, such as the Nanowave series of air filter materials, which use fine melt-blown fibers, which have stable efficiency, reduced pressure and good dust collection effects. Capability: The COAX series filter element adopts PP melt-blown fiber mesh, which can block coarse particles and PP/PE bi-component fiber mesh. It has a two-stage structure and can block fine particles. Delpore filter material uses fine-denier molten spray fiber mesh material with a diameter of 0.5 m~1.0 m, which can be used in high-end medicine, food and beverage and various industrial applications.

In addition, as industry needs continue to change, the filter material market will increasingly require suppliers who can develop innovative solutions to provide higher-value solutions for their customers and enterprises.

Obviously, the continuous development of the global manufacturing industry is rapidly promoting the development of new filter materials. The market in all fields needs higher performance filter materials to maintain the balance between filter efficiency and factory capacity, while meeting increasingly stringent emission regulations. . The world's leading filter material manufacturers have accelerated their global layout and the frequency of new product research and development, demonstrating the strong vitality and attractiveness of the nonwoven filter material market.