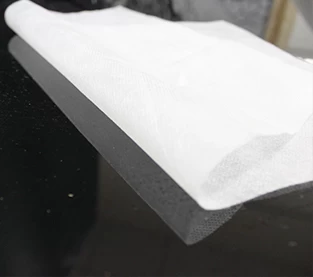

Product: ES Material Fiber Nonwoven Fabric For Packaging

Raw Material: PP+PE

Nonwoven Technology: thermal bonded

Dotted Design: dot or plain

Gram: 25 gsm - 30 gsm

Color: White

Specification: custom

Sample: Can be provided without charge, freight to be collect

Applications:

Medical(20-60gsm): face masks,diapers,bed sheets,curtains,pillow covers,sanitary,etc

Packaging(25-30gsm): tea bag, coffee bag/filter paper, dust-proof covers.etc

Product: ES Thermal Bonded Non Woven Fabric For Tea Bag

Raw Material: PP+PE

Nonwoven Technology: thermal bonded

Dotted Design: dot or plain

Gram: 25 gsm - 30 gsm

Color: White

Specification: custom

Sample: Can be provided without charge, freight to be collect

Applications:

Medical(20-60gsm): face masks,diapers,bed sheets,curtains,pillow covers,sanitary,etc

Packaging(25-30gsm): tea bag, coffee bag/filter paper, dust-proof covers.etc

Product: Composite Non Woven Paper Desiccant Packaging Material

MOQ: 1000 kg

Material: Composite Non Woven Paper

Specification: Custom sizes.

Design: Welcome custom logo and design. Welcome OEM.

Color: Full Color of CMYK,Pantone Color as customer requirements

Weight: Based on size & material,thickness

Delivery Time: 10-15 days after confirmed the final artwork and order

Product: Desiccant Wrapping Paper

MOQ: 1000 kg

Material: DuPont Material

Specification: Custom sizes.

Design: Welcome custom logo and design. Welcome OEM.

Color: Full Color of CMYK,Pantone Color as customer requirements

Weight: Based on size & material,thickness

Delivery Time: 10-15 days after confirmed the final artwork and order

Product: Bi-component Non Woven Fabric Desiccant Packaging Material

MOQ: 1000 kg

Material: Bi-component Non Woven Fabric

Specification: Custom sizes.

Design: Welcome custom logo and design. Welcome OEM.

Color: Full Color of CMYK,Pantone Color as customer requirements

Weight: Based on size & material,thickness

Delivery Time: 10-15 days after confirmed the final artwork and order

Product: Spunbond Non Woven Fabric Custom Desiccant Packaging Material

MOQ: 1000 kg

Material: Spunbond Non Woven Fabric

Specification: Custom sizes.

Design: Welcome custom logo and design. Welcome OEM.

Color: Full Color of CMYK,Pantone Color as customer requirements

Weight: Based on size & material,thickness

Delivery Time: 10-15 days after confirmed the final artwork and order

Physical modification is mainly to change the structure of the molecule to achieve the purpose of improving the hydrophilic effect, mainly the blending modification (ie, before spinning) and surface modification (ie, after spinning).

First, blending modification (pre-spinning modification)

According to the different addition period of the modified additive, it can be divided into master batch method, full granulation method and pre-spinning injection method.

1. Common masterbatch method

This is an important method for non-woven fabric manufacturers to produce hydrophilic nonwoven fabrics(Hydrophilic Nonwovens Supplier). First, the ordinary hydrophilic additive is made into a hydrophilic mother by a masterbatch manufacturer, and then mixed with PP to be melt-spun into a cloth,that is, a hydrophilic nonwoven fabric.

Advantages: Easy to produce, no need to add any equipment, and suitable for small batch production. In addition, its hydrophilic durability is strong.

2, full granulation method

The modifier, the PP chip and the auxiliary agent are uniformly mixed, and the particles are hydrolyzed by a screw to forma hydrophilic PP particle, which is then melt-spun into a cloth.

Advantages; good processability,long-lasting effect, and cloth can be used repeatedly.

3. Pre-spinning injection method

The hydrophilic agent, that is, the hydrophilic group polymer, is directly added to the main screw of the nonwoven fabric, and is uniformly spun directly mixed with the pp melt.

Advantages: The effect is lasting and thecloth can be used repeatedly.

Second, the surface hydrophilic finishing(spinning modification)

Hydrophilic finishing is a method for making a hydrophilic nonwoven fabric(Hydrophilic Non Woven Fabric Wholesale) with simple method, remarkable effect and lowcost. The main process flow is as follows:

Online spunbond hot-rolled non-woven fabric-roll coating or spraying hydrophilic agent - infrared or hot air dryer -winder - hydrophilic finishing non-woven fabric

Advantages: There is no problem of spinnability, the non-woven fabric(Water Absorbent Nonwovens Company) has a fast hydrophilic effect, high efficiency, and low price, which is 1/2-1/3 of the cost of the commonmasterbatch method. Suitable for mass production.

There are still many methods for making hydrophilic non-woven fabrics. Each manufacturer will choose the production method according to their own processes in production, and customers can alsomeet their own requirements for products.

To choose the products produced by different production methods.