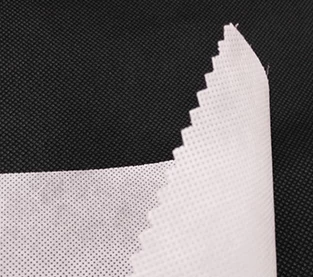

Product: ES Material Fiber Nonwoven Fabric For Packaging

Raw Material: PP+PE

Nonwoven Technology: thermal bonded

Dotted Design: dot or plain

Gram: 25 gsm - 30 gsm

Color: White

Specification: custom

Sample: Can be provided without charge, freight to be collect

Applications:

Medical(20-60gsm): face masks,diapers,bed sheets,curtains,pillow covers,sanitary,etc

Packaging(25-30gsm): tea bag, coffee bag/filter paper, dust-proof covers.etc

Product: ES Thermal Bonded Non Woven Fabric For Tea Bag

Raw Material: PP+PE

Nonwoven Technology: thermal bonded

Dotted Design: dot or plain

Gram: 25 gsm - 30 gsm

Color: White

Specification: custom

Sample: Can be provided without charge, freight to be collect

Applications:

Medical(20-60gsm): face masks,diapers,bed sheets,curtains,pillow covers,sanitary,etc

Packaging(25-30gsm): tea bag, coffee bag/filter paper, dust-proof covers.etc

Product: Composite Non Woven Paper Desiccant Packaging Material

MOQ: 1000 kg

Material: Composite Non Woven Paper

Specification: Custom sizes.

Design: Welcome custom logo and design. Welcome OEM.

Color: Full Color of CMYK,Pantone Color as customer requirements

Weight: Based on size & material,thickness

Delivery Time: 10-15 days after confirmed the final artwork and order

Product: Desiccant Wrapping Paper

MOQ: 1000 kg

Material: DuPont Material

Specification: Custom sizes.

Design: Welcome custom logo and design. Welcome OEM.

Color: Full Color of CMYK,Pantone Color as customer requirements

Weight: Based on size & material,thickness

Delivery Time: 10-15 days after confirmed the final artwork and order

Product: Bi-component Non Woven Fabric Desiccant Packaging Material

MOQ: 1000 kg

Material: Bi-component Non Woven Fabric

Specification: Custom sizes.

Design: Welcome custom logo and design. Welcome OEM.

Color: Full Color of CMYK,Pantone Color as customer requirements

Weight: Based on size & material,thickness

Delivery Time: 10-15 days after confirmed the final artwork and order

Product: Spunbond Non Woven Fabric Custom Desiccant Packaging Material

MOQ: 1000 kg

Material: Spunbond Non Woven Fabric

Specification: Custom sizes.

Design: Welcome custom logo and design. Welcome OEM.

Color: Full Color of CMYK,Pantone Color as customer requirements

Weight: Based on size & material,thickness

Delivery Time: 10-15 days after confirmed the final artwork and order

What is the measurement process of the filter cloth?

1. Let the belt filter press runnormally and adjust the motor speed to low speed.

2. Prepare materials and tools for measuring filter cloth, soft braided rope and tape measure.

3. When the metal joint appears on the filter belt(China Filter Nonwovens Manufacturer) of the filter press, attach the braided rope to the metal joint of the filter cloth for a sufficient period of time. Let the braided roperotate with the operation of the filter cloth.

4. When the braided rope rotates with the filter belt for one week, that is, when the metal joint appears, the braided rope is marked. This is to measure the length of the braided ropearound the filter cloth, ie the length of the filter cloth.

5. The same method measures thelength of another filter belt.

In the process of using the filter cloth(Non Woven Filter Fabric Wholesale),the wind speed of the filter is very high, which will directly lead to the maincause of bag damage. In the dust removal process, some units blindly save equipment costs and increase profits. The wind speed designed during the design process increases.

The inferior filter cloth(Non Woven Filter Material On Sales) does not respondto the user's use in a relatively short period of time, but this will shorten the service life of the filter bag, thereby giving the customer no money, butthe economic burden is relatively large. waste time.

The dust filter cloth needs to correctly select the dust bag suitable for the corresponding dustproof temperature. Ifthe temperature is too high during use, the media will cause the selected filter bag to exceed the normal operating temperature, thus shortening the lifeof the product. In severe cases, there will be burns.

In the process of selecting the filtercloth, it is necessary to measure and calculate the inlet temperature of the dust collector. Please choose a suitable dust bag when using. The processing ofthe bag is very important. In recent years, some small manufacturers have usedtheir sewing machines for processing and use. The quality of the raw materialsis relatively poor.