Product: Oem Brand Supermarket Multicolor Reusable Non Woven T-shirt Bag

MOQ: 10000 pcs

Feature: Flat,Folding,Luxury

Material: PP Non Woven Fabric

Size: Custom sizes.

Design: Welcome custom logo and design. Welcome OEM.

Color: Full Color of CMYK,Pantone Color as customer requirements

Weight: Based on size & material,thickness

Delivery Time: 10-15 days after confirmed the final artwork and order

Product: Custom Branded Supermarket Oem Shopping Non Woven Vest Tote Bag

MOQ: 10000 pcs

Feature: Flat,Folding,Luxury

Material: PP Non Woven Fabric

Size: Custom sizes.

Design: Welcome custom logo and design. Welcome OEM.

Color: Full Color of CMYK,Pantone Color as customer requirements

Weight: Based on size & material,thickness

Delivery Time: 10-15 days after confirmed the final artwork and order

Product: Wholesale Brand Supermarket Oem Non Woven T-Shirt Vest Bags

MOQ: 10000 pcs

Feature: Flat,Folding,Luxury

Material: PP Non Woven Fabric

Size: Custom sizes.

Design: Welcome custom logo and design. Welcome OEM.

Color: Full Color of CMYK,Pantone Color as customer requirements

Weight: Based on size & material,thickness

Delivery Time: 10-15 days after confirmed the final artwork and order

Product: Premium Convenient Brand Supermarket Shopping Nonwoven Vest Bag

MOQ: 10000 pcs

Feature: Flat,Folding,Luxury

Material: PP Non Woven Fabric

Size: Custom sizes.

Design: Welcome custom logo and design. Welcome OEM.

Color: Full Color of CMYK,Pantone Color as customer requirements

Weight: Based on size & material,thickness

Delivery Time: 10-15 days after confirmed the final artwork and order

Product: OEM Eco-Friendly Portable Reusable Shopping Non Woven Vest Bag

MOQ: 10000 pcs

Feature: Flat,Folding,Luxury

Material: PP Non Woven Fabric

Size: Custom sizes.

Design: Welcome custom logo and design. Welcome OEM.

Color: Full Color of CMYK,Pantone Color as customer requirements

Weight: Based on size & material,thickness

Delivery Time: 10-15 days after confirmed the final artwork and order

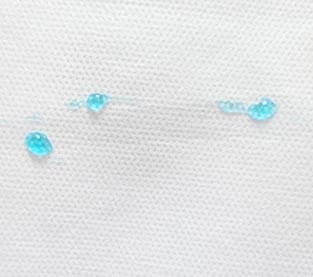

Spunbond nonwoven technology

The spunbonded nonwoven fabric(PP Non Woven Cloth Wholesale) as a protective material meets the requirements for strength and comfort, but is relatively weak in barrier properties. In response to this problem, fine denier spunbond technology has become a research hotspot. Germany's Freudenberg company first invented the two-component spunbond spunlace technology, using a hollow orange-spinning spinning assembly to extrude the melt stream from the orifice, after cooling and blowing, air drafting The filaments are formed on the web curtain, and the high-pressure spunlace technology is used for the opening and fixing of the filament. The barrier property is better than that of the ordinary spunbond or spunlace nonwoven material, so it can be used for medical protective materials.

Turkish non-woven fabric manufacturer Mogul has introduced a material that can be used in surgical gowns. Its fiber after opening is 100 times thinner than hair, it can block micro organisms, has anti-blood and alcohol properties, and has good properties. Moisture absorbing and heat insulating properties, the microporous structure and protective properties of this non-woven material make it an ideal material for medical protective clothing.

Meltblown nonwoven technology

The biggest characteristic of the melt-blown method is that the fiber is very fine, the structure is fluffy after self-bonding, the porosity is high, the average pore size is small, and the barrier property is very good, but the strength and wear resistance of the product are not high. Some people have made improvements on this basis, taking advantage of the spunbond technology, in the case of ensuring the fiber fineness, the short-distance cooling of the melt stream sprayed by hot air, and then through the thermal bonding fixed network It has been found that the strength of the product has been improved and can be applied to occasions where the strength is not too high.

Considering the problem of fine melt-blown fiber and poor compression back, 3M Company of the United States pioneered the development of intercalation melt-blown technology, in which it is sprayed into the meltblown fiber stream in the process of conventional melt-blown fiber production. Hollow elastic short fibers, under the same gram weight, the compression resilience of the product is greatly improved, the structure becomes more fluffy, and the gas permeability and moisture permeability are also improved; in addition, the passage of particles in the material becomes long and narrow, thereby The interception effect is increased, so that the barrier effect on the particles is greatly improved.

Another way to improve the breathability and moisture permeability of the meltblown nonwoven material(Non Woven Polypropylene Roll Manufacturer) while greatly improving the performance of blocking the fine particles is the electret method. The electret melt-blown nonwoven material can capture more particles with opposite charges by electrostatic adsorption mechanism, thereby greatly improving the filtration performance.

SMS composite technology

In view of the poor barrier effect of the spunbonded nonwoven material and the low strength of the meltblown nonwoven fabric, some people use the strength and wear resistance of the spunbonded fabric as the surface layer, and use the barrier property of the meltblown fabric as the barrier property. The core composite was prepared with an SMS composite nonwoven. In view of the fact that most of the current SMS composite protective materials(Medical Non Woven Products Supplier) use PP as a raw material and have poor protection against various radioactive materials, Liu Xing et al. of Tianjin University of Technology cooperated with a certain department of the Navy to coat the SMS materials with barium sulfate. It can prevent the penetration of radioactive materials, so it can be used for medical personnel to avoid unnecessary radioactive substances, causing lesions and better isolation and protection. The coating material can also be coated in the form of a sustained-release microcapsule, and when subjected to an external force, the microcapsule is broken and the protective property is enhanced.

Spunlace nonwoven technology

For the non-woven material of the short fiber which has been combed into a net and then hydroentangled and fixed, although it has a great advantage in the performance of soft skin, moisture absorption and breathability, it can only be used as a general medical material due to poor barrier properties. The protection performance is not very good. The University of Leeds in the United Kingdom developed a class of functional spunlace nonwoven materials in 2009. This material used a special device to form a hole structure in the spunlace process. Sustained release disinfectant capsules can be added to the structure.

The functional spunlace non-woven material with the micro-capsule of the sustained-release disinfectant can be made into a cross-infective protective material, placed in a door handle, a handrail, etc. where the hospital is in contact with the human body, when the person pushes the door or closes the door, the belt The patient will pass the germ through the hand to the contact handle. At this time, the microcapsule will release the disinfectant under the pressure of the human hand, effectively killing the bacteria, and other patients or healthy people will not be infected if they touch the handle again. This type of anti-cross-infective nonwoven protective material has been used in some hospitals in the UK and works very well.